- Teléfono0086 731 8564 8255

- Correo electrónicosales@cscsteel-manufacturing.com

-

- Teléfono0086 731 8564 8255

- Correo electrónicosales@cscsteel-manufacturing.com

-

Nombre del tipo:tapa, tapa enc, tapa de tubo, tapa sin costura, tapa de soldadura a tope, tapa de acero al carbono (tapa CS), tapa de acero dulce (tapa MS), tapa de aleación de acero (tapa AS), tapa de acero inoxidable (tapa SS) Semi elipsoidal ,

tapa semielipsoide, tapa elipsoide, tapa elipsoide, cabeza semiesférica

Tamaño: 1/2"-48"/(DN15-DN1200)

Conexión: soldadura

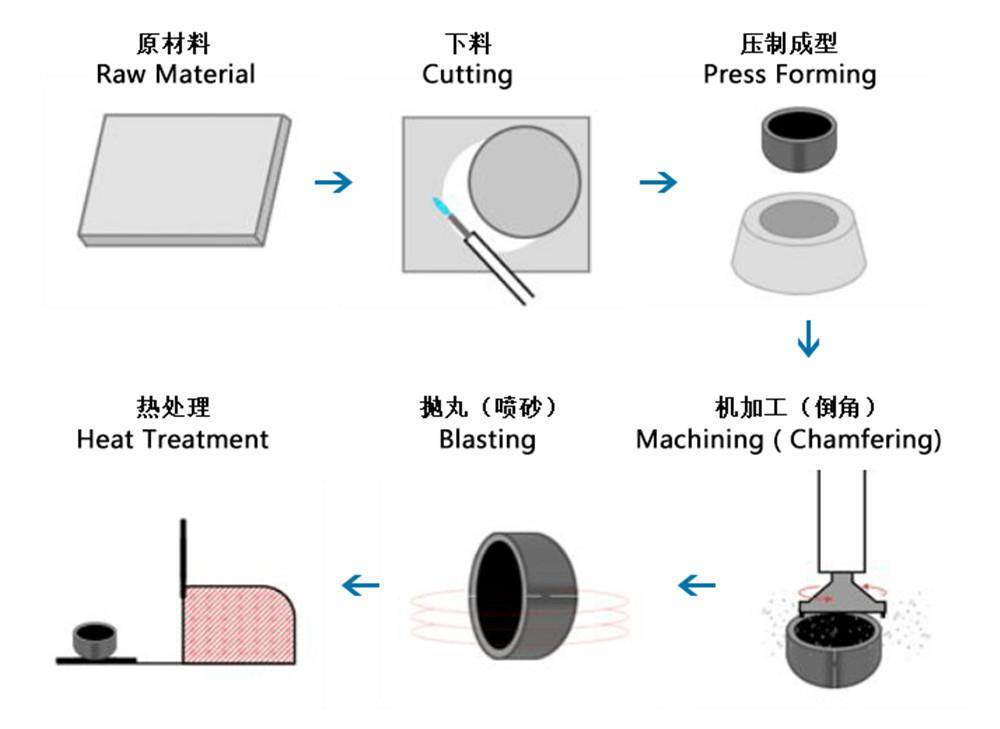

Técnica: forjado

Variedades: SCH10, SCH20, SGP, STD, SCH40, SCH80, SCH160

Material:

acero al carbono: ASTM A234 GR WPB, ST37.2, ST35.8……

acero aleado: A234 WP5/WP9/WP11/WP22/WP91, A420 WPL6, A860 WHPY 42/52/60/65/70/80……

acero inoxidable: A403 WP304/TP304, WP304L/TP304L, WP316/TP316, WP316L/TP316L, WP321/TP321, WP310/

WPBA234, A403-WP316, A403-WP316L, A403-WP317, A403-WP321, etc.

Estándar: BS, DIN, JIS, etc. ANSI B16.9/16.28, ASTM, API 5L, DIN2605/2615/2616, JIS2311/JIS 2312/JIS2313/ ASME B36.10M --- 1996, MSS SP43/MSS P75/ DIN2617 /GB-12459/GB-T13401, etc. …

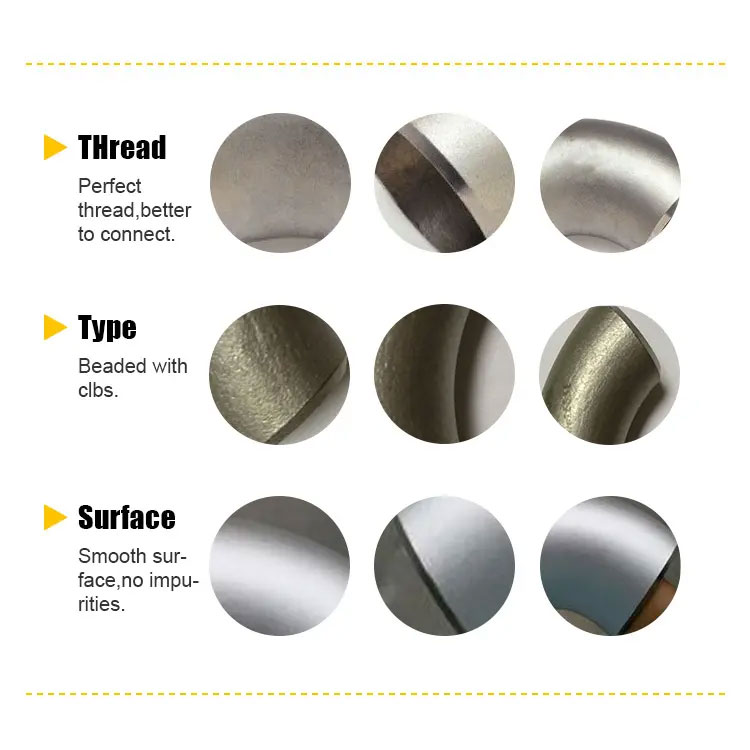

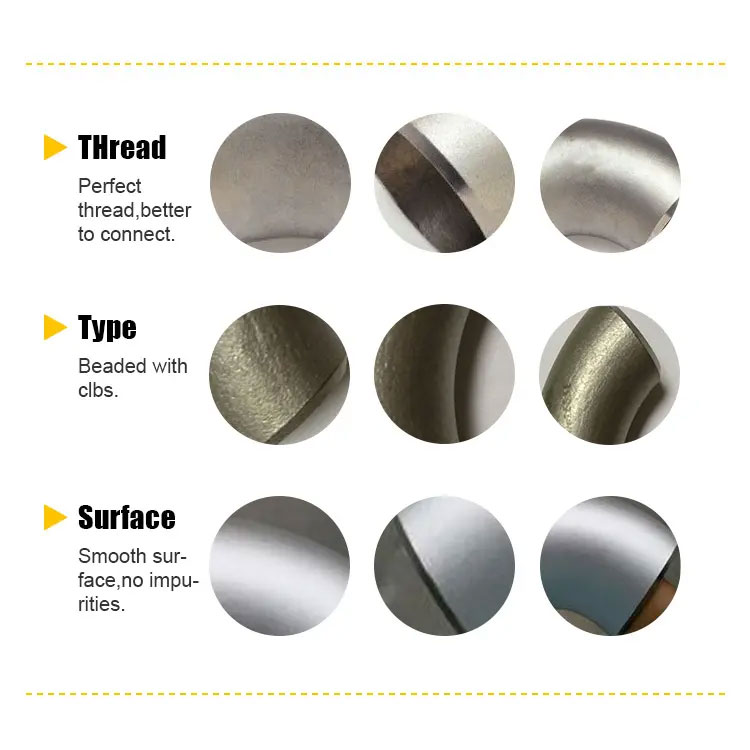

Tratamiento de la superficie: aceite negro a prueba de herrumbre, aceite transparente, granallado, pintura negra, aceite a prueba de herrumbre, aceite transparente, galvanizado, galvanizado en caliente

Aplicación: petróleo, electricidad, productos químicos, gas natural, construcción, construcción naval y otros campos debido a su alta presión, alta temperatura, etc.

Grados de material de tapa de tubería:

Tapa de tubería de acero inoxidable: ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Tapa de tubería de acero al carbono: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 y WPHY 70.

Tapa de tubería de acero al carbono de baja temperatura: ASTM A420 WPL3, A420 WPL6

Tapa de tubería de acero aleado:ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Tapa de tubería dúplex: ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462

Tapa de tubería de aleación de níquel:ASTM/ASME SB 336 UNS 2200 (NÍQUEL 200), UNS 2201 (NÍQUEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALEACIÓN 20/20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

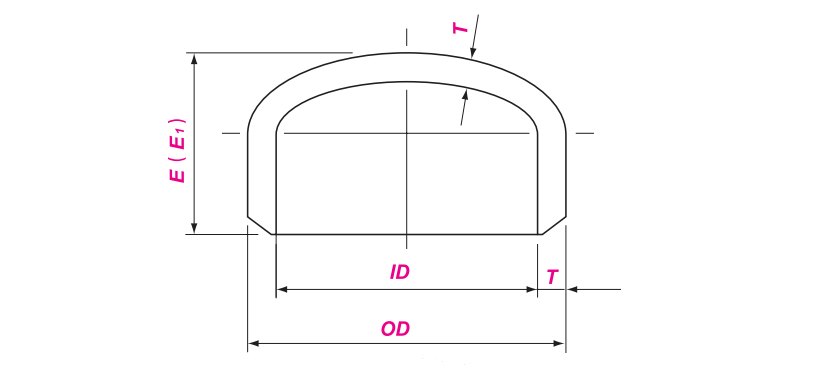

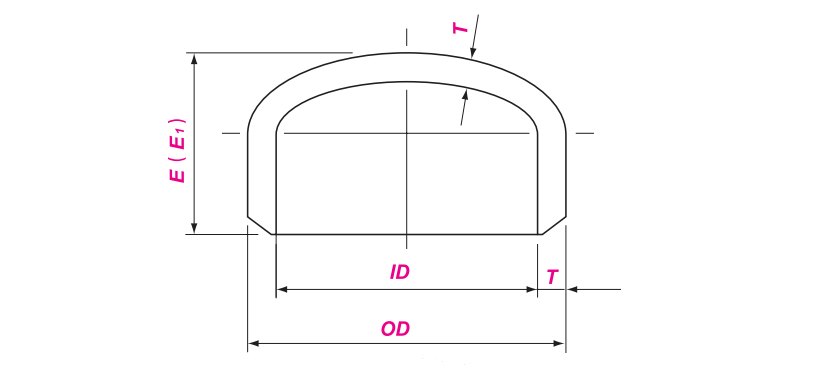

|

DN |

NSP |

sobredosis |

mi |

E1 |

|

15 |

1/2 |

21.3 |

25 |

25 |

|

20 |

3/4 |

26.7 |

25 |

25 |

|

25 |

1 |

33.4 |

38 |

38 |

|

32 |

1 1/4 |

42.2 |

38 |

38 |

|

40 |

1 1/2 |

48.3 |

38 |

38 |

|

50 |

2 |

60.3 |

38 |

44 |

|

sesenta y cinco |

2 1/2 |

73 |

38 |

51 |

|

80 |

3 |

88,9 |

51 |

64 |

|

90 |

3 1/2 |

101.6 |

64 |

76 |

|

100 |

4 |

114.3 |

64 |

76 |

|

125 |

5 |

141.3 |

76 |

89 |

|

150 |

6 |

168.3 |

89 |

102 |

|

200 |

8 |

219.1 |

102 |

127 |

|

250 |

10 |

273 |

127 |

152 |

|

300 |

12 |

323.9 |

152 |

178 |

|

350 |

14 |

355.6 |

165 |

191 |

|

400 |

dieciséis |

406.4 |

178 |

203 |

|

450 |

18 |

457 |

203 |

229 |

|

500 |

20 |

508 |

229 |

254 |

|

550 |

22 |

558.8 |

254 |

254 |

|

600 |

24 |

609.6 |

267 |

305 |

|

650 |

26 |

660.4 |

267 |

– |

|

700 |

28 |

711.2 |

267 |

– |

|

750 |

30 |

762 |

267 |

– |

|

800 |

32 |

812.8 |

267 |

– |

|

850 |

34 |

863.6 |

267 |

– |

|

900 |

36 |

914.4 |

267 |

– |

|

950 |

38 |

965.2 |

305 |

– |

|

1000 |

40 |

1016 |

305 |

– |

|

1050 |

42 |

1066.8 |

305 |

– |

|

1100 |

44 |

1117.8 |

343 |

– |

|

1150 |

46 |

1168.4 |

343 |

– |

|

1200 |

48 |

1219.2 |

343 |

– |

|

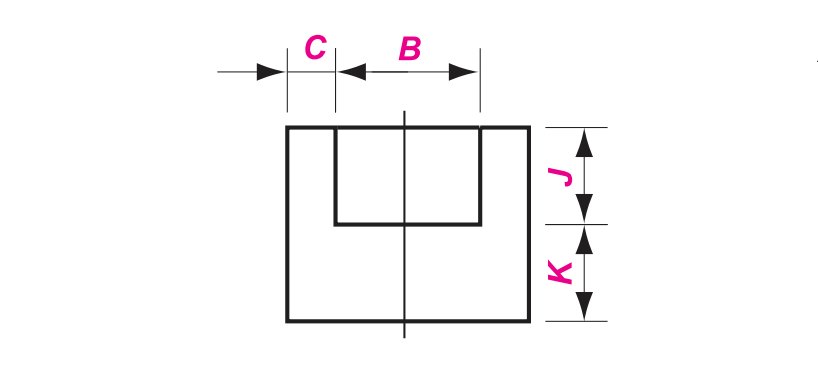

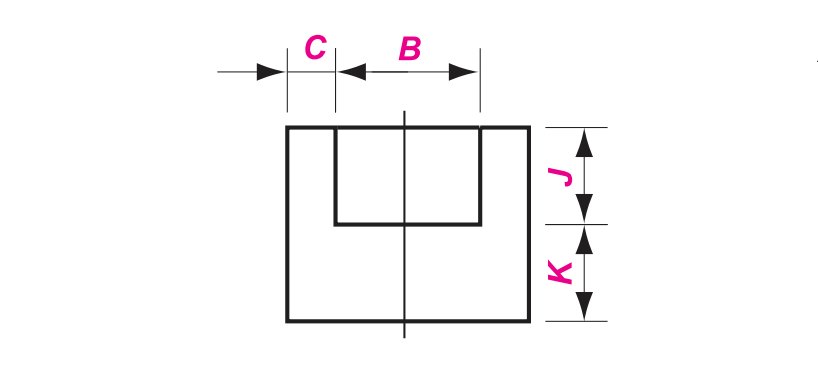

DN |

NSP |

B |

C |

j |

k |

|||||||

|

3000 |

6000 |

9000 |

3000 |

6000 |

9000 |

|||||||

|

Cra |

min |

Cra |

min |

Cra |

min |

|||||||

|

6 |

1/8 |

10.9 |

3.18 |

3.18 |

3.96 |

3.43 |

9.5 |

4.8 |

6.4 |

|||

|

8 |

1/4 |

14.3 |

3.78 |

3.3 |

4.6 |

4.01 |

9.5 |

4.8 |

6.4 |

|||

|

10 |

3/8 |

17.7 |

4.01 |

3.5 |

5.03 |

4.37 |

9.5 |

4.8 |

6.4 |

|||

|

15 |

1/2 |

21,9 |

4.67 |

4.09 |

5.97 |

5.18 |

9.53 |

8.18 |

9.5 |

6.4 |

7.9 |

11.2 |

|

20 |

3/4 |

27.3 |

4.9 |

4.27 |

6.96 |

6.04 |

9.78 |

8.56 |

12.5 |

6.4 |

7.9 |

12.7 |

|

25 |

1 |

34 |

5.69 |

4.98 |

7.92 |

6.93 |

11.38 |

9.96 |

12.5 |

9.6 |

11.2 |

14.2 |

|

32 |

1 1/4 |

42.8 |

6.07 |

5.28 |

7.92 |

6.93 |

12.14 |

10.62 |

12.5 |

9.6 |

11.2 |

14.2 |

|

40 |

1 1/2 |

48,9 |

6.35 |

5.54 |

8.92 |

7.8 |

12.7 |

11.12 |

12.5 |

11.2 |

12.7 |

15.7 |

|

50 |

2 |

61.2 |

6.93 |

6.04 |

10.92 |

9.5 |

13.84 |

12.12 |

dieciséis |

12.7 |

15.7 |

19 |

|

sesenta y cinco |

2 1/2 |

73,9 |

8.76 |

7.62 |

dieciséis |

15.7 |

19 |

|||||

|

80 |

3 |

89.9 |

9.52 |

8.3 |

dieciséis |

19 |

22.4 |

|||||

|

100 |

4 |

115.5 |

10.69 |

9.35 |

19 |

22.4 |

28.4 |

|||||

|

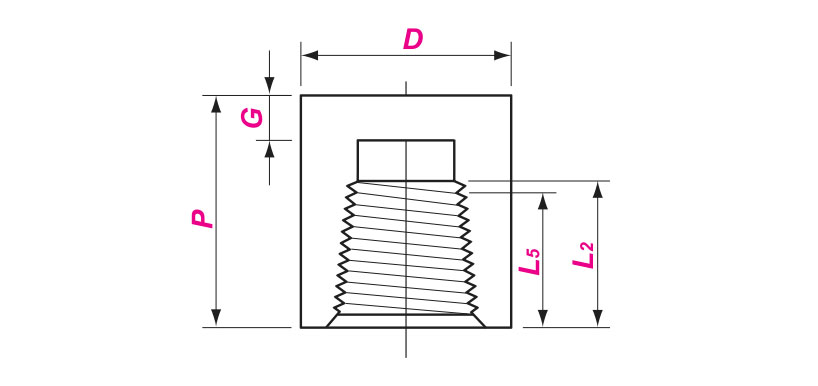

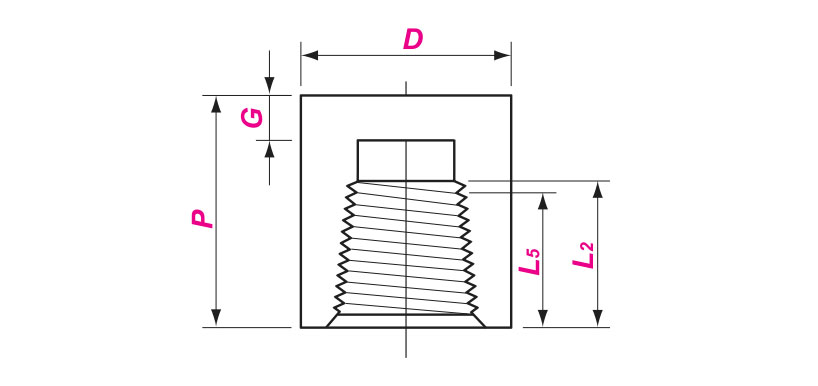

DN |

NSP |

PAG |

D |

GRAMO |

L5 |

L2 |

|||

|

3000 |

6000 |

3000 |

6000 |

3000 |

6000 |

||||

|

6 |

1/8 |

19 |

– |

dieciséis |

22 |

4.8 |

– |

6.4 |

6.7 |

|

8 |

1/4 |

25 |

27 |

19 |

25 |

4.8 |

6.4 |

8.1 |

10.2 |

|

10 |

3/8 |

25 |

27 |

22 |

32 |

4.8 |

6.4 |

9.1 |

10.4 |

|

15 |

1/2 |

32 |

33 |

28 |

38 |

6.4 |

7.9 |

10.9 |

13.6 |

|

20 |

3/4 |

37 |

38 |

35 |

44 |

6.4 |

7.9 |

12.7 |

13.9 |

|

25 |

1 |

41 |

43 |

44 |

57 |

9.7 |

11.2 |

14.7 |

17.3 |

|

32 |

1 1/4 |

44 |

46 |

57 |

64 |

9.7 |

11.2 |

17 |

18 |

|

40 |

1 1/2 |

44 |

48 |

64 |

76 |

11.2 |

12.7 |

17.8 |

18.4 |

|

50 |

2 |

48 |

51 |

76 |

92 |

12.7 |

15.7 |

19 |

19.2 |

|

sesenta y cinco |

2 1/2 |

60 |

64 |

92 |

108 |

15.7 |

19 |

23.6 |

28,9 |

|

80 |

3 |

sesenta y cinco |

68 |

108 |

127 |

19 |

22.4 |

25,9 |

30.5 |

|

100 |

4 |

68 |

75 |

140 |

159 |

22.4 |

28.4 |

27.7 |

33 |

Si tiene alguna pregunta, no dude en ponerse en contacto con continental Iron and Steel co., Ltd. Gracias por adelantado. Bienvenido

|

DN |

NSP |

sobredosis |

mi |

E1 |

|

15 |

1/2 |

21.3 |

25 |

25 |

|

20 |

3/4 |

26.7 |

25 |

25 |

|

25 |

1 |

33.4 |

38 |

38 |

|

32 |

1 1/4 |

42.2 |

38 |

38 |

|

40 |

1 1/2 |

48.3 |

38 |

38 |

|

50 |

2 |

60.3 |

38 |

44 |

|

sesenta y cinco |

2 1/2 |

73 |

38 |

51 |

|

80 |

3 |

88,9 |

51 |

64 |

|

90 |

3 1/2 |

101.6 |

64 |

76 |

|

100 |

4 |

114.3 |

64 |

76 |

|

125 |

5 |

141.3 |

76 |

89 |

|

150 |

6 |

168.3 |

89 |

102 |

|

200 |

8 |

219.1 |

102 |

127 |

|

250 |

10 |

273 |

127 |

152 |

|

300 |

12 |

323.9 |

152 |

178 |

|

350 |

14 |

355.6 |

165 |

191 |

|

400 |

dieciséis |

406.4 |

178 |

203 |

|

450 |

18 |

457 |

203 |

229 |

|

500 |

20 |

508 |

229 |

254 |

|

550 |

22 |

558.8 |

254 |

254 |

|

600 |

24 |

609.6 |

267 |

305 |

|

650 |

26 |

660.4 |

267 |

– |

|

700 |

28 |

711.2 |

267 |

– |

|

750 |

30 |

762 |

267 |

– |

|

800 |

32 |

812.8 |

267 |

– |

|

850 |

34 |

863.6 |

267 |

– |

|

900 |

36 |

914.4 |

267 |

– |

|

950 |

38 |

965.2 |

305 |

– |

|

1000 |

40 |

1016 |

305 |

– |

|

1050 |

42 |

1066.8 |

305 |

– |

|

1100 |

44 |

1117.8 |

343 |

– |

|

1150 |

46 |

1168.4 |

343 |

– |

|

1200 |

48 |

1219.2 |

343 |

– |

|

DN |

NSP |

B |

C |

j |

k |

|||||||

|

3000 |

6000 |

9000 |

3000 |

6000 |

9000 |

|||||||

|

Cra |

min |

Cra |

min |

Cra |

min |

|||||||

|

6 |

1/8 |

10.9 |

3.18 |

3.18 |

3.96 |

3.43 |

9.5 |

4.8 |

6.4 |

|||

|

8 |

1/4 |

14.3 |

3.78 |

3.3 |

4.6 |

4.01 |

9.5 |

4.8 |

6.4 |

|||

|

10 |

3/8 |

17.7 |

4.01 |

3.5 |

5.03 |

4.37 |

9.5 |

4.8 |

6.4 |

|||

|

15 |

1/2 |

21,9 |

4.67 |

4.09 |

5.97 |

5.18 |

9.53 |

8.18 |

9.5 |

6.4 |

7.9 |

11.2 |

|

20 |

3/4 |

27.3 |

4.9 |

4.27 |

6.96 |

6.04 |

9.78 |

8.56 |

12.5 |

6.4 |

7.9 |

12.7 |

|

25 |

1 |

34 |

5.69 |

4.98 |

7.92 |

6.93 |

11.38 |

9.96 |

12.5 |

9.6 |

11.2 |

14.2 |

|

32 |

1 1/4 |

42.8 |

6.07 |

5.28 |

7.92 |

6.93 |

12.14 |

10.62 |

12.5 |

9.6 |

11.2 |

14.2 |

|

40 |

1 1/2 |

48,9 |

6.35 |

5.54 |

8.92 |

7.8 |

12.7 |

11.12 |

12.5 |

11.2 |

12.7 |

15.7 |

|

50 |

2 |

61.2 |

6.93 |

6.04 |

10.92 |

9.5 |

13.84 |

12.12 |

dieciséis |

12.7 |

15.7 |

19 |

|

sesenta y cinco |

2 1/2 |

73,9 |

8.76 |

7.62 |

dieciséis |

15.7 |

19 |

|||||

|

80 |

3 |

89.9 |

9.52 |

8.3 |

dieciséis |

19 |

22.4 |

|||||

|

100 |

4 |

115.5 |

10.69 |

9.35 |

19 |

22.4 |

28.4 |

|||||

|

DN |

NSP |

PAG |

D |

GRAMO |

L5 |

L2 |

|||

|

3000 |

6000 |

3000 |

6000 |

3000 |

6000 |

||||

|

6 |

1/8 |

19 |

– |

dieciséis |

22 |

4.8 |

– |

6.4 |

6.7 |

|

8 |

1/4 |

25 |

27 |

19 |

25 |

4.8 |

6.4 |

8.1 |

10.2 |

|

10 |

3/8 |

25 |

27 |

22 |

32 |

4.8 |

6.4 |

9.1 |

10.4 |

|

15 |

1/2 |

32 |

33 |

28 |

38 |

6.4 |

7.9 |

10.9 |

13.6 |

|

20 |

3/4 |

37 |

38 |

35 |

44 |

6.4 |

7.9 |

12.7 |

13.9 |

|

25 |

1 |

41 |

43 |

44 |

57 |

9.7 |

11.2 |

14.7 |

17.3 |

|

32 |

1 1/4 |

44 |

46 |

57 |

64 |

9.7 |

11.2 |

17 |

18 |

|

40 |

1 1/2 |

44 |

48 |

64 |

76 |

11.2 |

12.7 |

17.8 |

18.4 |

|

50 |

2 |

48 |

51 |

76 |

92 |

12.7 |

15.7 |

19 |

19.2 |

|

sesenta y cinco |

2 1/2 |

60 |

64 |

92 |

108 |

15.7 |

19 |

23.6 |

28,9 |

|

80 |

3 |

sesenta y cinco |

68 |

108 |

127 |

19 |

22.4 |

25,9 |

30.5 |

|

100 |

4 |

68 |

75 |

140 |

159 |

22.4 |

28.4 |

27.7 |

33 |

Si tiene alguna pregunta, no dude en ponerse en contacto con continental Iron and Steel co., Ltd. Gracias por adelantado. Bienvenido