- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

Product Name:Titanium alloy pipe

Outer Diameter :6-2500mm, (3/8"-100")

Thickness :0.3-150mm,(SCH10-XXS)

Length: 2000mm, 2500mm, 3000mm, 5800mm, 6000mm,12000mm, etc

Standard :ASTM,AISI,JIS,,GB, DIN,,EN

Surface :BA,2B,NO.1,NO.4,4K,HL,8K

Certification :ISO, SGS,BV

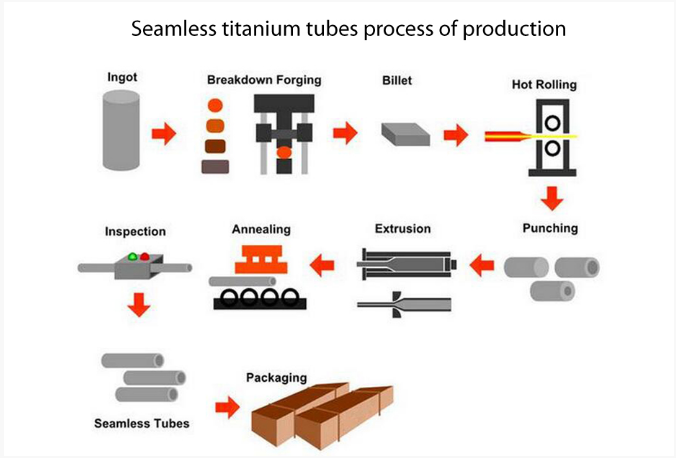

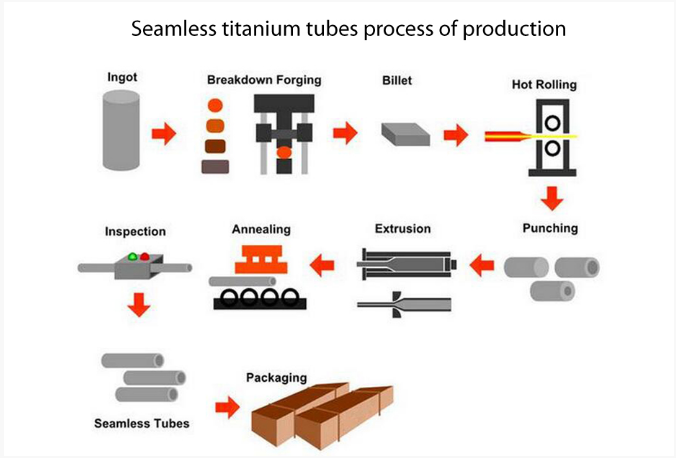

Technique :Cold Drawn Seamless Tube / Welded pipe

Edge :Mill Edge Slit Edge

Application: It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components.

It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc.

NGREDIENT:

| ASTM/ASME | GB | JIS | Element Content(wt%) | Mechanical Properties | |||||||

| N,max | C,max | H,max | Fe,max | O,max | Others |

Strength Of Extension Mpa,min |

Ductility %,min |

||||

| Pure Titanium | Gr.1 | TA1 | Class1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | 240 | 24 | |

| Gr.2 | TA2 | Class2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 345 | 20 | ||

| Gr.3 | TA3 | Class3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | 450 | 18 | ||

| Gr.4 | TA4 | Class4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | 550 | 15 | ||

| Titanium Alloy | Gr.5 |

TC4 Ti-6A1-4V |

Class60 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 |

AI:5.5-6.75 V:3.5-4.5 |

895 | 10 |

| Gr.7 | TA9 | Class12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | Pd:0.12-0.25 | 345 | 20 | |

| Gr.9 | TC2 | Class61 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 |

AI:2.5-3.5 V:2.0-3.0 |

620 | 15 | |

| Gr.11 | TA9-1 | Class11 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | Pd:0.12-0.25 | 240 | 24 | |

| Gr.23 | TC4 ELI | Class60E | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 |

AI:5.5-6.5 V:3.5-4.5 |

828 | 10 | |

Types of Titanium Alloys

Ti 6AL-4V

Ti 6AL ELI

Ti 3Al 2.5

Ti 5Al-2.5Sn

| ASTM A 480 | Flat Rolled and Heat Resisting Steel - Sheet, Plate, Coil and Strip |

| ASTM E 8 | Metallic Material Tension Testing |

| ASTM E 120 | Ti and Ti-Base Alloys, Semi-Guided Chemical Analysis |

| ASTM E 290 | Metallic Materials Ductility Bend Test |

| ASTM-F136-98e1 | Wrought Ti-6 Aluminum-4 Vanadium ELI (Extra Low Interstitial) Alloy (UNSR56401) for Surgical Implant Applications |

| ASTM-F67-00 | Unalloyed Ti for Surgical Implant Applications (UNS R50250 / R50400 / R50550 / R50700) |

| ASTM-F1108-97a | Ti6AL4V Alloy Castings for Surgical Implants (UNS R56406) |

| ASTM-F-620-00 | Alpha Plus Beta Ti Alloy Forgings Products |

| ASTM-F1472-99 | Wrought Ti-6 Aluminum-4 Alloy UNS R56400 |

| ASTM-F1341-99 | Unalloyed Ti Wire UNS R50250, R50400, R50550, R50700 |

| ASTM-F1295-97a | UNS R56700 Ti-6 Aluminum-7 Niobium Alloy |

| ASTM B265-99 | Strips, Sheets, Plates |

| ASTM-B299-99 | Sponges |

| ASTM-B338-99 | Seamless, Welded Tubing for Heat Exchangers, Boilers, Condensers |

| ASTM-B348-00 | Bar, rod, Billet |

| ASTM-B363-00 | Seamless and Welded Buttweld Pipe Fittings (Unalloyed) |

| ASTM-B367-93 (1998) | Casting products |

| ASTM-B381-00 | Forging products |

| ASTM-B861-00 | Seamless Pipes |

| ASTM-B862-99 | Welded Pipes |

| ASTM-B863-99a | Wires |

| Commercially Pure Titanium Alloy | |

|---|---|

| (CP) CODE | min. ksi or Yield Strength |

| CP-1 | (70 KSI) |

| CP-2 | (55 KSI) |

| CP-3 | (40 KSI) |

| CP-4 | (30 KSI) |

| Alpha Titanium Alloys (A) | |

| CODE | Composition Chart |

| A-1 | 5AL-2.5Sn |

| A-2 | 5AL-2.5Sn (ELI) |

| A-3 | 6AL-2Cb-1Ta-0.8Mo |

| A-4 | 8AL-1Mo-1V |

| Alpha-Beta Titanium Alloy | |

| (AB) CODE | Composition Chart |

| AB-1 | 6AL-4V |

| AB-2 | 6AL-4V (ELI) |

| AB-3 | 6AL-6V-2Sn |

| AB-4 | 6AL-2Sn-4Zr-2Mo |

| AB-5 | 3.AL-2.5V |

| AB-6 | 8Mn |

| Beta Titanium Alloys (B) | |

| CODE | Composition Chart |

| B-1 | 13V-11Cr-3AL |

| B-2 | 11.5Mo-6Zr-4.5Sn |

| B-3 | 3AL-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3AL |

| Grade | Information |

|---|---|

| 5 | Ti alloy (6% aluminium, 4% vanadium) |

| 7 | Unalloyed Ti plus 0.12% to 0.25% palladium, standard oxygen, medium strength |

| 9 | Ti alloy (3% aluminium, 2.5% vanadium), high strength. Mainly aerospace applications |

| 11 | Unalloyed Ti plus 0.12% to 0.25% palladium, low oxygen/ strength |

| 12 | Ti alloy (0.3% molybdenum, 0.8% nickel), high strength |

| 13 | Ti alloy (0.5% nickel, 0.05% ruthenium), low oxygen |

| 14 | Ti alloy (0.5% nickel, 0.05% ruthenium), standard oxygen |

| 15 | Ti alloy (0.5% nickel, 0.05% ruthenium), medium oxygen |

| 16 | Unalloyed Ti plus 0.04% to 0.08% palladium, medium strength, standard oxygen |

| 17 | Unalloyed Ti plus 0.04% to 0.08% palladium, low oxygen/ strength |

| 18 | Ti alloy (3% aluminium, 2.5% vanadium plus 0.04% to 0.08% palladium), |

| 19 | Ti alloy (3% aluminium, 8% vanadium, 4% zirconium, 6% chromium, 4% molybdenum) |

| 20 | Ti alloy (3% aluminium, 8% vanadium, 4% zirconium, 6% chromium, 4% molybdenum) plus 0.04% to 0.08% palladium |

| 21 | Ti alloy (15% molybdenum, 2.7% niobium, 3% aluminium, 0.25% silicon) |

| 23 | Ti alloy (4% vanadium, 6% aluminium, extra low interstitial, ELI) |

| 24 | Ti alloy (4% vanadium, 6% aluminium) plus 0.04% to 0.08% palladium |

| 25 | Ti alloy (4% vanadium, 6% aluminium) plus 0.04% to 0.08% palladium, 0.3% to 0.8% nickel |

| 26 | Unalloyed Ti plus 0.08% to 0.14% ruthenium, medium strength, standard oxygen |

| 27 | Unalloyed Ti plus 0.08% to 0.14% ruthenium, low oxygen/ strength |

| 28 | Ti alloy (2.5% vanadium, 3% aluminium) plus 0.08% to 0.14% ruthenium |

| 29 | Ti alloy 0.08% to 0.14% ruthenium, (6% aluminium, 4% vanadium with ELI) |

| Ultimate Tensile Strength minimum | Yield Strength minimum | Elongation minimum | |||

|---|---|---|---|---|---|

| GRADE | KSI | Mpa | KSI | Mpa | % |

| Gr 1 | 35 | 240 | 25 | 170 | 24 |

| Gr 2 | 50 | 345 | 40 | 275 | 20 |

| Gr 3 | 65 | 450 | 55 | 380 | 18 |

| Gr 4 | 80 | 550 | 70 | 485 | 15 |

| Ti 2% Pd (Gr.7) | 50 | 345 | 40 | 275 | 20 |

| Gr 12 | 70 | 483 | 50 | 345 | 18 |

| Ti-6AL-4V | 130 | 895 | 120 | 830 | 10 |

| Ti-4AL-4Mo-1.5Sn | 170 | 1160 | 125 | 850 | 10 |

| Ti-10-2-3 | 180 | 1250 | 160 | 1100 | 8 |

| Ti-15-3 | 185 | 1280 | 160 | 1100 | 10 |

| Ti-6-2-4-2 | 160 | 1100 | 120 | 830 | 10 |

| Ti-6-2-4-6 | 190 | 1300 | 140 | 970 | 10 |

| Melting point range | 1670 Deg C, 3038 Deg F, 1943 K |

| Boiling point range | 3287 Deg C, 5949 Deg F, 3560 K |

| Density (g cm−3) | 4.506 |

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!

NGREDIENT:

| ASTM/ASME | GB | JIS | Element Content(wt%) | Mechanical Properties | |||||||

| N,max | C,max | H,max | Fe,max | O,max | Others |

Strength Of Extension Mpa,min |

Ductility %,min |

||||

| Pure Titanium | Gr.1 | TA1 | Class1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | 240 | 24 | |

| Gr.2 | TA2 | Class2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 345 | 20 | ||

| Gr.3 | TA3 | Class3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | 450 | 18 | ||

| Gr.4 | TA4 | Class4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | 550 | 15 | ||

| Titanium Alloy | Gr.5 |

TC4 Ti-6A1-4V |

Class60 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 |

AI:5.5-6.75 V:3.5-4.5 |

895 | 10 |

| Gr.7 | TA9 | Class12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | Pd:0.12-0.25 | 345 | 20 | |

| Gr.9 | TC2 | Class61 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 |

AI:2.5-3.5 V:2.0-3.0 |

620 | 15 | |

| Gr.11 | TA9-1 | Class11 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | Pd:0.12-0.25 | 240 | 24 | |

| Gr.23 | TC4 ELI | Class60E | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 |

AI:5.5-6.5 V:3.5-4.5 |

828 | 10 | |

Types of Titanium Alloys

Ti 6AL-4V

Ti 6AL ELI

Ti 3Al 2.5

Ti 5Al-2.5Sn

| ASTM A 480 | Flat Rolled and Heat Resisting Steel - Sheet, Plate, Coil and Strip |

| ASTM E 8 | Metallic Material Tension Testing |

| ASTM E 120 | Ti and Ti-Base Alloys, Semi-Guided Chemical Analysis |

| ASTM E 290 | Metallic Materials Ductility Bend Test |

| ASTM-F136-98e1 | Wrought Ti-6 Aluminum-4 Vanadium ELI (Extra Low Interstitial) Alloy (UNSR56401) for Surgical Implant Applications |

| ASTM-F67-00 | Unalloyed Ti for Surgical Implant Applications (UNS R50250 / R50400 / R50550 / R50700) |

| ASTM-F1108-97a | Ti6AL4V Alloy Castings for Surgical Implants (UNS R56406) |

| ASTM-F-620-00 | Alpha Plus Beta Ti Alloy Forgings Products |

| ASTM-F1472-99 | Wrought Ti-6 Aluminum-4 Alloy UNS R56400 |

| ASTM-F1341-99 | Unalloyed Ti Wire UNS R50250, R50400, R50550, R50700 |

| ASTM-F1295-97a | UNS R56700 Ti-6 Aluminum-7 Niobium Alloy |

| ASTM B265-99 | Strips, Sheets, Plates |

| ASTM-B299-99 | Sponges |

| ASTM-B338-99 | Seamless, Welded Tubing for Heat Exchangers, Boilers, Condensers |

| ASTM-B348-00 | Bar, rod, Billet |

| ASTM-B363-00 | Seamless and Welded Buttweld Pipe Fittings (Unalloyed) |

| ASTM-B367-93 (1998) | Casting products |

| ASTM-B381-00 | Forging products |

| ASTM-B861-00 | Seamless Pipes |

| ASTM-B862-99 | Welded Pipes |

| ASTM-B863-99a | Wires |

| Commercially Pure Titanium Alloy | |

|---|---|

| (CP) CODE | min. ksi or Yield Strength |

| CP-1 | (70 KSI) |

| CP-2 | (55 KSI) |

| CP-3 | (40 KSI) |

| CP-4 | (30 KSI) |

| Alpha Titanium Alloys (A) | |

| CODE | Composition Chart |

| A-1 | 5AL-2.5Sn |

| A-2 | 5AL-2.5Sn (ELI) |

| A-3 | 6AL-2Cb-1Ta-0.8Mo |

| A-4 | 8AL-1Mo-1V |

| Alpha-Beta Titanium Alloy | |

| (AB) CODE | Composition Chart |

| AB-1 | 6AL-4V |

| AB-2 | 6AL-4V (ELI) |

| AB-3 | 6AL-6V-2Sn |

| AB-4 | 6AL-2Sn-4Zr-2Mo |

| AB-5 | 3.AL-2.5V |

| AB-6 | 8Mn |

| Beta Titanium Alloys (B) | |

| CODE | Composition Chart |

| B-1 | 13V-11Cr-3AL |

| B-2 | 11.5Mo-6Zr-4.5Sn |

| B-3 | 3AL-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3AL |

| Grade | Information |

|---|---|

| 5 | Ti alloy (6% aluminium, 4% vanadium) |

| 7 | Unalloyed Ti plus 0.12% to 0.25% palladium, standard oxygen, medium strength |

| 9 | Ti alloy (3% aluminium, 2.5% vanadium), high strength. Mainly aerospace applications |

| 11 | Unalloyed Ti plus 0.12% to 0.25% palladium, low oxygen/ strength |

| 12 | Ti alloy (0.3% molybdenum, 0.8% nickel), high strength |

| 13 | Ti alloy (0.5% nickel, 0.05% ruthenium), low oxygen |

| 14 | Ti alloy (0.5% nickel, 0.05% ruthenium), standard oxygen |

| 15 | Ti alloy (0.5% nickel, 0.05% ruthenium), medium oxygen |

| 16 | Unalloyed Ti plus 0.04% to 0.08% palladium, medium strength, standard oxygen |

| 17 | Unalloyed Ti plus 0.04% to 0.08% palladium, low oxygen/ strength |

| 18 | Ti alloy (3% aluminium, 2.5% vanadium plus 0.04% to 0.08% palladium), |

| 19 | Ti alloy (3% aluminium, 8% vanadium, 4% zirconium, 6% chromium, 4% molybdenum) |

| 20 | Ti alloy (3% aluminium, 8% vanadium, 4% zirconium, 6% chromium, 4% molybdenum) plus 0.04% to 0.08% palladium |

| 21 | Ti alloy (15% molybdenum, 2.7% niobium, 3% aluminium, 0.25% silicon) |

| 23 | Ti alloy (4% vanadium, 6% aluminium, extra low interstitial, ELI) |

| 24 | Ti alloy (4% vanadium, 6% aluminium) plus 0.04% to 0.08% palladium |

| 25 | Ti alloy (4% vanadium, 6% aluminium) plus 0.04% to 0.08% palladium, 0.3% to 0.8% nickel |

| 26 | Unalloyed Ti plus 0.08% to 0.14% ruthenium, medium strength, standard oxygen |

| 27 | Unalloyed Ti plus 0.08% to 0.14% ruthenium, low oxygen/ strength |

| 28 | Ti alloy (2.5% vanadium, 3% aluminium) plus 0.08% to 0.14% ruthenium |

| 29 | Ti alloy 0.08% to 0.14% ruthenium, (6% aluminium, 4% vanadium with ELI) |

| Ultimate Tensile Strength minimum | Yield Strength minimum | Elongation minimum | |||

|---|---|---|---|---|---|

| GRADE | KSI | Mpa | KSI | Mpa | % |

| Gr 1 | 35 | 240 | 25 | 170 | 24 |

| Gr 2 | 50 | 345 | 40 | 275 | 20 |

| Gr 3 | 65 | 450 | 55 | 380 | 18 |

| Gr 4 | 80 | 550 | 70 | 485 | 15 |

| Ti 2% Pd (Gr.7) | 50 | 345 | 40 | 275 | 20 |

| Gr 12 | 70 | 483 | 50 | 345 | 18 |

| Ti-6AL-4V | 130 | 895 | 120 | 830 | 10 |

| Ti-4AL-4Mo-1.5Sn | 170 | 1160 | 125 | 850 | 10 |

| Ti-10-2-3 | 180 | 1250 | 160 | 1100 | 8 |

| Ti-15-3 | 185 | 1280 | 160 | 1100 | 10 |

| Ti-6-2-4-2 | 160 | 1100 | 120 | 830 | 10 |

| Ti-6-2-4-6 | 190 | 1300 | 140 | 970 | 10 |

| Melting point range | 1670 Deg C, 3038 Deg F, 1943 K |

| Boiling point range | 3287 Deg C, 5949 Deg F, 3560 K |

| Density (g cm−3) | 4.506 |

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!