- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

ERW pipes are made from hot rolled coils produced by steel mills. All incoming coils are verified against the chemical and mechanical property test certificates received from the mill. The forming phase of ERW pipe starts with a single wide steel strip. The width of the strip is approximately equal to the circumference of the pipe to be produced. The edges of the coll are clipped to the prespecified width in the cutting line. The process includes uncoiling and flattening of the coil as well as processing it. The front end of each coil is sheared and squared for feeding into the rolling mill. Then connect this end with the coil end of the outgoing coil to maintain continuity of production and reduce loss.

Pre-production Meeting;

Pre-production Meeting;

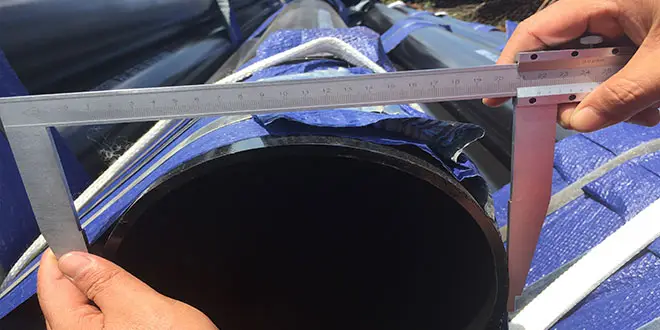

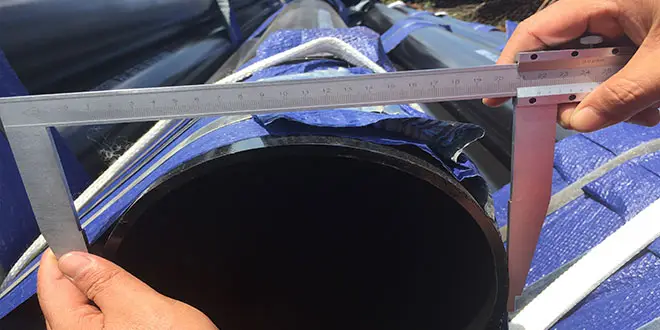

Pipe Dimension On-site Inspection

Welding online inspection

Welding seam online inspection

Pipe NDT (X ray/RT/UT) Test Inspection

Hydro Static Test Inspection

Pipe cutting & length Inspection

Pipe Dimension On-site Inspection

Welding online inspection

Welding seam online inspection

Pipe NDT (X ray/RT/UT) Test Inspection

Hydro Static Test Inspection

Pipe cutting & length Inspection

Pipe Chemical Property Inspection

Pipe Mechanical Property Inspection

Pipe Surface Inspection

Pipe Dimension Inspection

Pipe Marking & Traceability Inspection

Pipe Packing & Protection Inspection

Pipe Transportation Monitoring

Pipe Chemical Property Inspection

Pipe Mechanical Property Inspection

Pipe Surface Inspection

Pipe Dimension Inspection

Pipe Marking & Traceability Inspection

Pipe Packing & Protection Inspection

Pipe Transportation Monitoring