- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

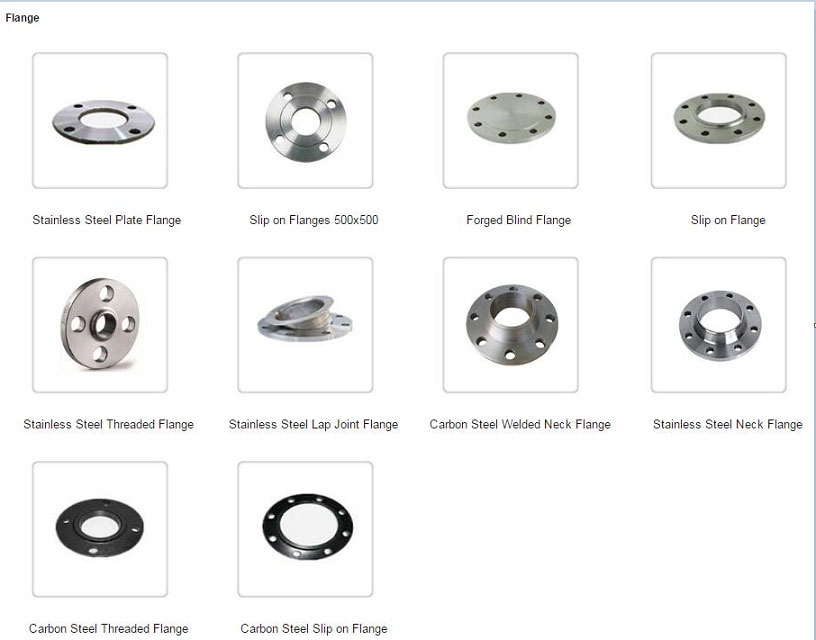

FORGED FLANGE :

1) ANSI B16.5, ASME B16.47 FLANGE

2) EN1092-1 FLANGE

3) DIN FLANGE

4) GOST FLANGE

5) JIS B2220 FALNGE

|

BLIND FLANGES Blind flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind flanges, the standard height is 1/16" for blind flanges under 400#. For blind flanges of 400# and up, the standard blind flange raised face height is 1/4". Material: Carbon, Alloy and Stainless Steel Standards: ASTM A105, ASTM A182 Sizes: 1/2'' to 24'', Customized up to 48'' Thickness: Schedule 10(S) to SCH 160 Pressure Ratings: Class 150 to 2500 Face Type: RF, RTJ |

SLIP-ON FLANGES Slip on pipe flanges are typically provided with a raised or flat face. When a raised face is necessary for slip on pipe flanges, the standard height is 1/16" for slip on pipe flanges under 400#. For slip on pipe flanges of 400# and up, the standard slip on pipe flange raised face height is 1/4". Standard: ASTM A105, ASTM A182 Material: Carbon Steel, Alloy Steel, Stainless Steel Size: 1/2'' to 24'', customized up to 60'' Pressure Ratings: Class 150 to Class 2500 Face Type: RF, RTJ |

WELD NECK FLANGES Weld neck pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for weld neck pipe flanges, the standard height is 1/16" for weld neck pipe flanges under 400#. For weld neck pipe flanges of 400# and up, the standard weld neck pipe flange raised face height is 1/4". Material: Carbon, Alloy and Stainless Steel Standards: ASTM A105, ASTM A182 Sizes: 1/2'' to 24'', Customized up to 48'' Thickness: Schedule 10(S) to SCH 160 Pressure Ratings: Class 150 to 2500 Face Type: RF, RTJ |

|

LAP JOINT FLANGES Slip on Pipe flanges with a hub have published specifications that range from 1/2" thru 24". Sizes above 24" are produced as lap joints to slip on dimensions. Coastal Flange provides Lap Joint pipe flanges in all material grades, specifications and sizes. Carbon steel: ASTM A105, A350 LF2 Stainless steel: A182 F304/F304L/F316/F316L/F321 Alloy steel: ASTM A182, GR F1, F11, F22, F5, F9, F91 Outer Diameters: 1/2'' to 24'' Wall Thickness Schedule: SCH 10, SCH 40, SCH 160 |

THREADED FLANGES Threaded pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for threaded pipe flanges, the standard height is 1/16" for threaded pipe flanges under 400#. For threaded pipe flanges of 400# and up, the standard threaded pipe flange raised face height is 1/4". Standard: ASTM A105, ASTM A182 Material: Carbon Steel, Stainless Steel, Alloy Steel Size Range: 1/2'', 1'', 2'', 3'', 4'' to 24'' Pressure Class: Class 150 to 2500 Face: Raised face (RF), Ring type joint (RTJ) |

SOCKET WELD FLANGES Socket Weld pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for socket weld pipe flanges, the standard height is 1/16" for socket weld pipe flanges under 400#. For socket weld pipe flanges of 400# and up, the standard socket weld pipe flange raised face height is 1/4". Standard: Carbon steel ASTM A105, ASTM A350 LF1/2, ASTM A181 Alloy steel ASTM A182 F5, F9, F11, F22, F91 Stainless steel ASTM A182 F304/L, F316/L Outer Diameters: 1/2 inch to 24 inch, up to 2500# Special made: 24'' to 60'', up to 900# Wall Thickness: Schedule 40 to 160 Pressure Ratings: Class 150 to Class 2500 Face Type: RF, RTJ |

| Welding neck |

| 1, Preferred for high-pressure, subzero or elevated temperature |

| 2, Hub is tapered and bored to match pipe’s inside diameter so flow is not restricted, preventing turbulence and reducing erosion |

| 3, Easily radiographed and provides excellent stress distribution |

| Slip-on |

| 1, Not normally used in high-stress applications due to low hub and weld attachment |

| 2, Silps over outside of pipe |

| 3, Inside of flange welded at hub and end of pipe |

| Lap joint |

| 1, Used where bolt alignment or access for cleaning is required |

| 2, Similar to slip-on flange when used with lap joint stub end |

| 3, Radius at intersection of flange face and bore to match lap joint stub end |

| Threaded |

| 1, Used where welding would would be hazardous |

| 2, Designed for low-pressure and non-cyclic applications |

| 3, Bore is threaded to match pipe thread |

| 4, Tapered to seal pipe and flanges |

| Socket welding |

| 1, For small-diameter chemical processes, hydraulic and stream distribution lines |

| 2, Similar to slip-on flange |

| 3, Counter bore matches pipe bore, allowing unrestricted flow |

| 4, Counter bore from hub side fits pipe’s outer diameter – can insert pipe in socket with fillet weld at hub |

| Blind |

| 1, Used to close ends of piping |

| 2, Has no bore |

| 3, Permits access to sealed lines |

| Other flanges |

|

Orifice, Expander, Reducing, Lightweight, Studding Outlets, Long Weld Necks,Metric, Navy Drawings, Customer Drawings |

| Stainless Steel Pipe Flange |

| ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L |

| Carbon Steel Pipe Flange |

| ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52 |

| Low Temperature Pipe Flange |

| ASTM A350 LF2, LF3, LF6 |

| Alloy Steel Pipe Flange |

| ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex & Super Duplex Steel Pipe Flange |

| ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Nickel Alloy Pipe Flange |

| UNS 10276 (HASTELLOY C 276), UNS 6625 (INCONEL 625), UNS 6601 (INCONEL 601), UNS 6600 (INCONEL 600), UNS 8825 (INCONEL 825), UNS 8020 (ALLOY 20 / 20 CB 3), UNS 4400 (MONEL 400), UNS 2201 (NICKEL 201), ASTM / ASME SB 336 UNS 2200 (NICKEL 200) |

| High Yield Pipe Flanges |

| ASTM A694 F42, F52, F60, F65, F70 |

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!

|

BLIND FLANGES Blind flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind flanges, the standard height is 1/16" for blind flanges under 400#. For blind flanges of 400# and up, the standard blind flange raised face height is 1/4". Material: Carbon, Alloy and Stainless Steel Standards: ASTM A105, ASTM A182 Sizes: 1/2'' to 24'', Customized up to 48'' Thickness: Schedule 10(S) to SCH 160 Pressure Ratings: Class 150 to 2500 Face Type: RF, RTJ |

SLIP-ON FLANGES Slip on pipe flanges are typically provided with a raised or flat face. When a raised face is necessary for slip on pipe flanges, the standard height is 1/16" for slip on pipe flanges under 400#. For slip on pipe flanges of 400# and up, the standard slip on pipe flange raised face height is 1/4". Standard: ASTM A105, ASTM A182 Material: Carbon Steel, Alloy Steel, Stainless Steel Size: 1/2'' to 24'', customized up to 60'' Pressure Ratings: Class 150 to Class 2500 Face Type: RF, RTJ |

WELD NECK FLANGES Weld neck pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for weld neck pipe flanges, the standard height is 1/16" for weld neck pipe flanges under 400#. For weld neck pipe flanges of 400# and up, the standard weld neck pipe flange raised face height is 1/4". Material: Carbon, Alloy and Stainless Steel Standards: ASTM A105, ASTM A182 Sizes: 1/2'' to 24'', Customized up to 48'' Thickness: Schedule 10(S) to SCH 160 Pressure Ratings: Class 150 to 2500 Face Type: RF, RTJ |

|

LAP JOINT FLANGES Slip on Pipe flanges with a hub have published specifications that range from 1/2" thru 24". Sizes above 24" are produced as lap joints to slip on dimensions. Coastal Flange provides Lap Joint pipe flanges in all material grades, specifications and sizes. Carbon steel: ASTM A105, A350 LF2 Stainless steel: A182 F304/F304L/F316/F316L/F321 Alloy steel: ASTM A182, GR F1, F11, F22, F5, F9, F91 Outer Diameters: 1/2'' to 24'' Wall Thickness Schedule: SCH 10, SCH 40, SCH 160 |

THREADED FLANGES Threaded pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for threaded pipe flanges, the standard height is 1/16" for threaded pipe flanges under 400#. For threaded pipe flanges of 400# and up, the standard threaded pipe flange raised face height is 1/4". Standard: ASTM A105, ASTM A182 Material: Carbon Steel, Stainless Steel, Alloy Steel Size Range: 1/2'', 1'', 2'', 3'', 4'' to 24'' Pressure Class: Class 150 to 2500 Face: Raised face (RF), Ring type joint (RTJ) |

SOCKET WELD FLANGES Socket Weld pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for socket weld pipe flanges, the standard height is 1/16" for socket weld pipe flanges under 400#. For socket weld pipe flanges of 400# and up, the standard socket weld pipe flange raised face height is 1/4". Standard: Carbon steel ASTM A105, ASTM A350 LF1/2, ASTM A181 Alloy steel ASTM A182 F5, F9, F11, F22, F91 Stainless steel ASTM A182 F304/L, F316/L Outer Diameters: 1/2 inch to 24 inch, up to 2500# Special made: 24'' to 60'', up to 900# Wall Thickness: Schedule 40 to 160 Pressure Ratings: Class 150 to Class 2500 Face Type: RF, RTJ |

| Welding neck |

| 1, Preferred for high-pressure, subzero or elevated temperature |

| 2, Hub is tapered and bored to match pipe’s inside diameter so flow is not restricted, preventing turbulence and reducing erosion |

| 3, Easily radiographed and provides excellent stress distribution |

| Slip-on |

| 1, Not normally used in high-stress applications due to low hub and weld attachment |

| 2, Silps over outside of pipe |

| 3, Inside of flange welded at hub and end of pipe |

| Lap joint |

| 1, Used where bolt alignment or access for cleaning is required |

| 2, Similar to slip-on flange when used with lap joint stub end |

| 3, Radius at intersection of flange face and bore to match lap joint stub end |

| Threaded |

| 1, Used where welding would would be hazardous |

| 2, Designed for low-pressure and non-cyclic applications |

| 3, Bore is threaded to match pipe thread |

| 4, Tapered to seal pipe and flanges |

| Socket welding |

| 1, For small-diameter chemical processes, hydraulic and stream distribution lines |

| 2, Similar to slip-on flange |

| 3, Counter bore matches pipe bore, allowing unrestricted flow |

| 4, Counter bore from hub side fits pipe’s outer diameter – can insert pipe in socket with fillet weld at hub |

| Blind |

| 1, Used to close ends of piping |

| 2, Has no bore |

| 3, Permits access to sealed lines |

| Other flanges |

|

Orifice, Expander, Reducing, Lightweight, Studding Outlets, Long Weld Necks,Metric, Navy Drawings, Customer Drawings |

| Stainless Steel Pipe Flange |

| ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L |

| Carbon Steel Pipe Flange |

| ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52 |

| Low Temperature Pipe Flange |

| ASTM A350 LF2, LF3, LF6 |

| Alloy Steel Pipe Flange |

| ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex & Super Duplex Steel Pipe Flange |

| ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Nickel Alloy Pipe Flange |

| UNS 10276 (HASTELLOY C 276), UNS 6625 (INCONEL 625), UNS 6601 (INCONEL 601), UNS 6600 (INCONEL 600), UNS 8825 (INCONEL 825), UNS 8020 (ALLOY 20 / 20 CB 3), UNS 4400 (MONEL 400), UNS 2201 (NICKEL 201), ASTM / ASME SB 336 UNS 2200 (NICKEL 200) |

| High Yield Pipe Flanges |

| ASTM A694 F42, F52, F60, F65, F70 |

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!