- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

Pre-production Meeting;

Production preparation;

Steel Coil certificate audit;

Steel Coil quantity,visual,traceability check

Steel Coil Dimension inspection;

Steel Coil chemical property inspection;

Steel Coil Mechanical property inspection

Pre-production Meeting;

Production preparation;

Steel Coil certificate audit;

Steel Coil quantity,visual,traceability check

Steel Coil Dimension inspection;

Steel Coil chemical property inspection;

Steel Coil Mechanical property inspection

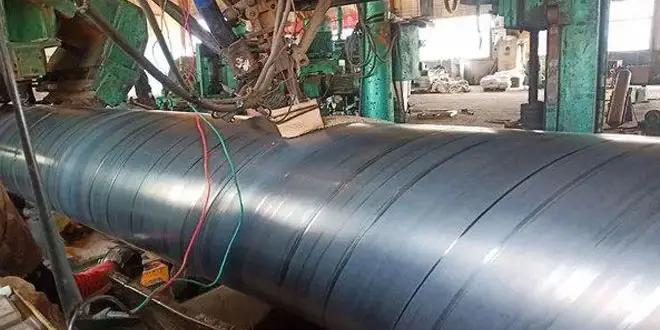

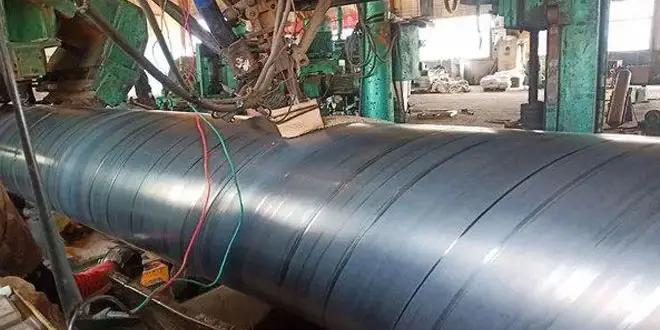

Pipe Dimension On-site Inspection

Welding online inspection

Pipe NDT (X ray/RT/UT) Test Inspection

Hydro Static Test Inspection

Pipe cutting & length Inspection

Pipe Dimension On-site Inspection

Welding online inspection

Pipe NDT (X ray/RT/UT) Test Inspection

Hydro Static Test Inspection

Pipe cutting & length Inspection

Pipe Chemical Property Inspection

Pipe Mechanical Property Inspection

Pipe Surface Inspection

Pipe Dimension Inspection

Pipe Marking & Traceability Inspection

Pipe Packing & Protection Inspection

Pipe Transportation Monitoring

Pipe Chemical Property Inspection

Pipe Mechanical Property Inspection

Pipe Surface Inspection

Pipe Dimension Inspection

Pipe Marking & Traceability Inspection

Pipe Packing & Protection Inspection

Pipe Transportation Monitoring