- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

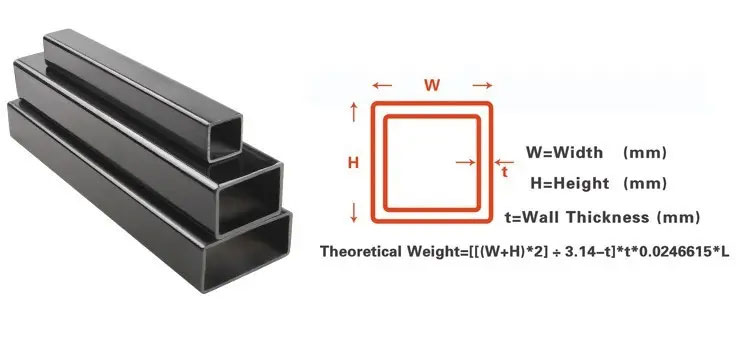

RHS and SHS tubeare a welded structural grade tubing,depending on its size and wall thickness. Either grade is ideal for all structural applications, general fabrication, manufacturing and repairs.

Square hollow sectionis widely used in industrial maintenance, agricultural implements, transportation equipment, truck beds, trailers, frames, etc. Its box-shape configuration allows for much greater strength and rigidity compared to angles or channels.

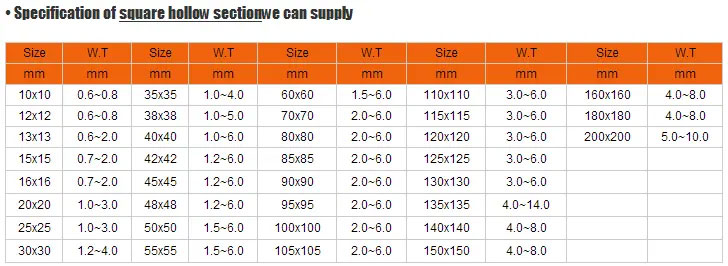

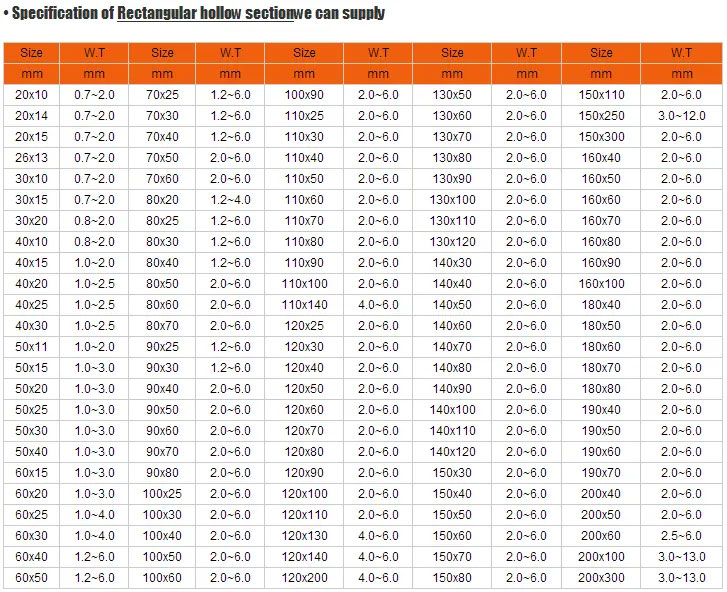

Specification:

Square Hollow Section:

Outer diameter: 10mm*10mm - 500mm*500mm

Wall thickness: 0.5mm - 20mm

LENGTH: 0.1meters - 18meters

Rectangular Hollow Section:

Outer diameter: 10mm*20mm - 400mm*600mm

Wall thickness: 0.5mm - 20mm

LENGTH: 0.1meters- 18meters

Standard:ASTM A500, ASTM A53, EN 10210, EN 10219, JIS G 3466, BS 1387, BS 6323. GB: Q195, Q215, Q235, Q345. ASTM: GR A, GR B, GR C, GR D. JIS: SS330, SS440, SS490. EN BS: S185, S235JR, S235 G2H

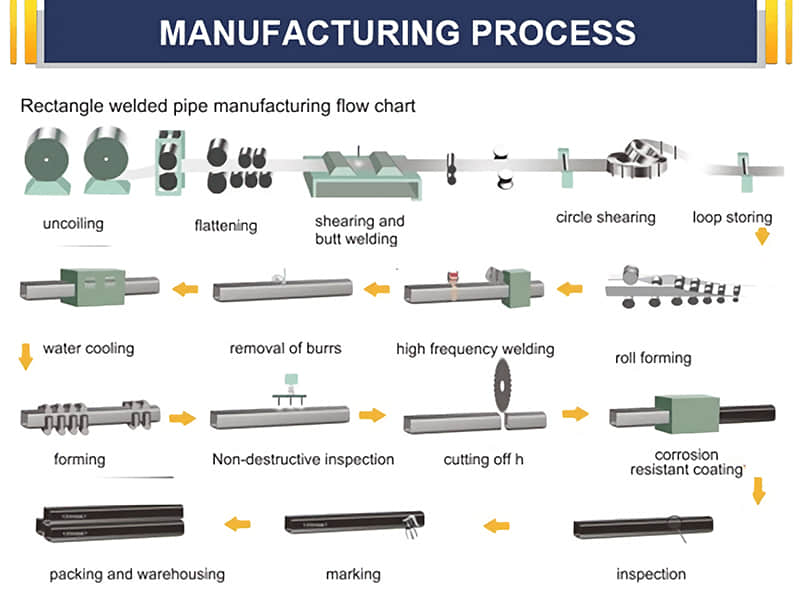

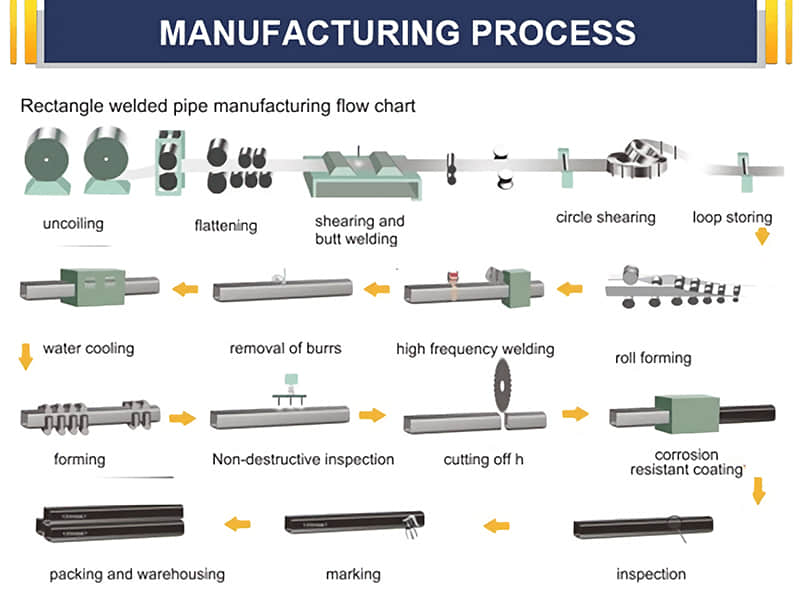

Process Type:Hot Rolled/Hot Expanded, Electric Resistance/High Frequency,Cold rolled , Annealed(welded),

End:Square Cut, Burr Removed

Surface:Bare, Black Painting, Lightly Oiled,Black annealing,Galvanized

Packing:Waterproof Paper Wrapped, Steel Strips Bundled, Two Tags on Each Bundle

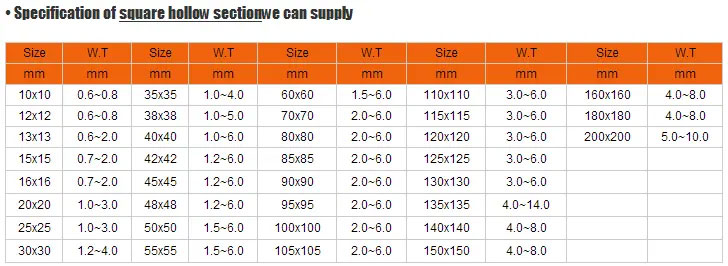

Size chart of mild steel square tube

|

Size |

Wall thickness |

Size |

Wall thickness |

Size |

Wall thickness |

Size |

Wall thickness |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

10×10 |

0.6-0.8 |

42×42 |

1.2-6.0 |

90×90 |

2.5-6.0 |

150×150 |

4.0-8.0 |

|

12×12 |

0.6-0.8 |

45×45 |

1.2-6.0 |

95×95 |

2.5-6.0 |

160×160 |

4.0-8.0 |

|

13×13 |

0.6-2.0 |

48×48 |

1.2-6.0 |

100×100 |

2.5-6.0 |

180×180 |

4.0-8.0 |

|

15×15 |

0.7-2.0 |

50×50 |

1.5-6.0 |

105×105 |

2.5-6.0 |

200×200 |

5.0-10.0 |

|

16×16 |

0.7-2.0 |

55×55 |

1.5-6.0 |

110×110 |

3.0-6.0 |

220×220 |

8.0-25.0 |

|

20×20 |

1.0-3.0 |

60×60 |

1.5-6.0 |

115×115 |

3.0-6.0 |

250×250 |

8.0-25.0 |

|

25×25 |

1.0-3.0 |

65×65 |

2.0-6.0 |

120×120 |

3.0-6.0 |

280×280 |

8.0-25.0 |

|

30×30 |

1.2-4.0 |

70×70 |

2.0-6.0 |

125×125 |

3.0-6.0 |

300×300 |

8.0-25.0 |

|

35×35 |

1.0-4.0 |

75×75 |

2.0-6.0 |

130×130 |

3.0-6.0 |

350×350 |

8.0-25.0 |

|

38×38 |

1.0-5.0 |

80×80 |

2.5-6.0 |

135×135 |

4.0-14.0 |

400×400 |

8.0-25.0 |

|

40×40 |

1.0-6.0 |

85×85 |

2.5-6.0 |

140×140 |

4.0-8.0 |

450×450 |

8.0-25.0 |

Standard chart:

|

Chemical composition of material |

|||||

|

Grade |

element |

C |

Mn |

P |

S |

|

ASTM A500 Gr.b |

% |

0.05%-0.23% |

0.3%-0.6% |

0.04% |

0.04% |

|

Acc.to EN10027/1 |

Acc.to EN10027/2 |

C% max (Norminal W.T.(mm) |

Si% max

|

Mn% max

|

P% max

|

S% max

|

N% max

|

|

|

and IC 10 |

≤ 40 |

|||||||

|

S235JRH |

1.0039 |

0.17 |

0.2 |

- |

1.4 |

0.045 |

0.045 |

0.009 |

|

S275JOH |

1.0149 |

0.2 |

0.22 |

- |

1.5 |

0.04 |

0.04 |

0.009 |

|

S275J2H |

1.0138 |

0.2 |

0.22 |

- |

1.5 |

0.035 |

0.035 |

- |

|

S355JOH |

1.0547 |

0.22 |

0.22 |

0.55 |

1.6 |

0.04 |

0.04 |

0.009 |

|

S355J2H |

1.0576 |

0.22 |

0.22 |

0.55 |

1.6 |

0.035 |

0.035 |

- |

|

Mechanical properties of material |

|||

|

Grade |

Yield Strength |

Tensile Strength |

Elongation |

|

A500.Gr.b |

46 ksi |

58 ksi |

23% |

|

A513.GR.B |

72 ksi |

87 ksi |

10% |

|

Norm |

Yield Strength |

Tensile Strength |

Min.elogation |

Min.percent properties |

||||||||

|

Acc.to EN10027/1 and IC 10

|

Acc.to EN10027/2

|

Norminal W.T.mm |

Norminal W.T.mm |

Longit. |

Cross |

Test temperature°C |

Average min.impact value |

|||||

|

≤16

|

>6 |

>40 |

<3

|

≤3≤65

|

Norminal W.T.mm |

|||||||

|

≤65

|

≤65

|

≤40

|

>40 |

>40 |

≤65

|

|||||||

|

≤65 |

≤40 |

|||||||||||

|

S253JRH |

1.0039 |

235 |

225 |

215 |

360-510 |

340-470 |

26 |

25 |

24 |

23 |

20 |

27 |

|

S275JOH |

1.0149 |

275 |

265 |

255 |

410-580 |

410-560 |

22 |

21 |

20 |

19 |

0 |

27 |

|

S275J2H |

1.0138 |

275 |

265 |

255 |

430-560 |

410-560 |

22 |

21 |

20 |

19 |

-20 |

27 |

|

S355JOH |

1.0547 |

355 |

345 |

335 |

510-680 |

490-630 |

22 |

21 |

20 |

19 |

0 |

27 |

|

S355J2H |

1.0576 |

355 |

345 |

335 |

510-680 |

490-630 |

22 |

21 |

20 |

19 |

-20 |

27 |

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!

Size chart of mild steel square tube

|

Size |

Wall thickness |

Size |

Wall thickness |

Size |

Wall thickness |

Size |

Wall thickness |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

10×10 |

0.6-0.8 |

42×42 |

1.2-6.0 |

90×90 |

2.5-6.0 |

150×150 |

4.0-8.0 |

|

12×12 |

0.6-0.8 |

45×45 |

1.2-6.0 |

95×95 |

2.5-6.0 |

160×160 |

4.0-8.0 |

|

13×13 |

0.6-2.0 |

48×48 |

1.2-6.0 |

100×100 |

2.5-6.0 |

180×180 |

4.0-8.0 |

|

15×15 |

0.7-2.0 |

50×50 |

1.5-6.0 |

105×105 |

2.5-6.0 |

200×200 |

5.0-10.0 |

|

16×16 |

0.7-2.0 |

55×55 |

1.5-6.0 |

110×110 |

3.0-6.0 |

220×220 |

8.0-25.0 |

|

20×20 |

1.0-3.0 |

60×60 |

1.5-6.0 |

115×115 |

3.0-6.0 |

250×250 |

8.0-25.0 |

|

25×25 |

1.0-3.0 |

65×65 |

2.0-6.0 |

120×120 |

3.0-6.0 |

280×280 |

8.0-25.0 |

|

30×30 |

1.2-4.0 |

70×70 |

2.0-6.0 |

125×125 |

3.0-6.0 |

300×300 |

8.0-25.0 |

|

35×35 |

1.0-4.0 |

75×75 |

2.0-6.0 |

130×130 |

3.0-6.0 |

350×350 |

8.0-25.0 |

|

38×38 |

1.0-5.0 |

80×80 |

2.5-6.0 |

135×135 |

4.0-14.0 |

400×400 |

8.0-25.0 |

|

40×40 |

1.0-6.0 |

85×85 |

2.5-6.0 |

140×140 |

4.0-8.0 |

450×450 |

8.0-25.0 |

Standard chart:

|

Chemical composition of material |

|||||

|

Grade |

element |

C |

Mn |

P |

S |

|

ASTM A500 Gr.b |

% |

0.05%-0.23% |

0.3%-0.6% |

0.04% |

0.04% |

|

Acc.to EN10027/1 |

Acc.to EN10027/2 |

C% max (Norminal W.T.(mm) |

Si% max

|

Mn% max

|

P% max

|

S% max

|

N% max

|

|

|

and IC 10 |

≤ 40 |

|||||||

|

S235JRH |

1.0039 |

0.17 |

0.2 |

- |

1.4 |

0.045 |

0.045 |

0.009 |

|

S275JOH |

1.0149 |

0.2 |

0.22 |

- |

1.5 |

0.04 |

0.04 |

0.009 |

|

S275J2H |

1.0138 |

0.2 |

0.22 |

- |

1.5 |

0.035 |

0.035 |

- |

|

S355JOH |

1.0547 |

0.22 |

0.22 |

0.55 |

1.6 |

0.04 |

0.04 |

0.009 |

|

S355J2H |

1.0576 |

0.22 |

0.22 |

0.55 |

1.6 |

0.035 |

0.035 |

- |

|

Mechanical properties of material |

|||

|

Grade |

Yield Strength |

Tensile Strength |

Elongation |

|

A500.Gr.b |

46 ksi |

58 ksi |

23% |

|

A513.GR.B |

72 ksi |

87 ksi |

10% |

|

Norm |

Yield Strength |

Tensile Strength |

Min.elogation |

Min.percent properties |

||||||||

|

Acc.to EN10027/1 and IC 10

|

Acc.to EN10027/2

|

Norminal W.T.mm |

Norminal W.T.mm |

Longit. |

Cross |

Test temperature°C |

Average min.impact value |

|||||

|

≤16

|

>6 |

>40 |

<3

|

≤3≤65

|

Norminal W.T.mm |

|||||||

|

≤65

|

≤65

|

≤40

|

>40 |

>40 |

≤65

|

|||||||

|

≤65 |

≤40 |

|||||||||||

|

S253JRH |

1.0039 |

235 |

225 |

215 |

360-510 |

340-470 |

26 |

25 |

24 |

23 |

20 |

27 |

|

S275JOH |

1.0149 |

275 |

265 |

255 |

410-580 |

410-560 |

22 |

21 |

20 |

19 |

0 |

27 |

|

S275J2H |

1.0138 |

275 |

265 |

255 |

430-560 |

410-560 |

22 |

21 |

20 |

19 |

-20 |

27 |

|

S355JOH |

1.0547 |

355 |

345 |

335 |

510-680 |

490-630 |

22 |

21 |

20 |

19 |

0 |

27 |

|

S355J2H |

1.0576 |

355 |

345 |

335 |

510-680 |

490-630 |

22 |

21 |

20 |

19 |

-20 |

27 |

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!