- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

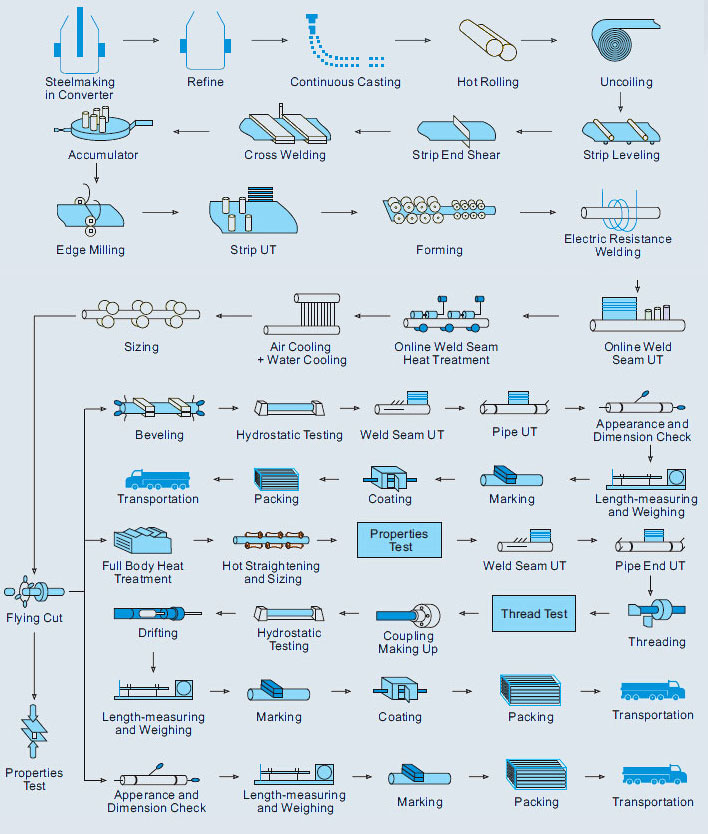

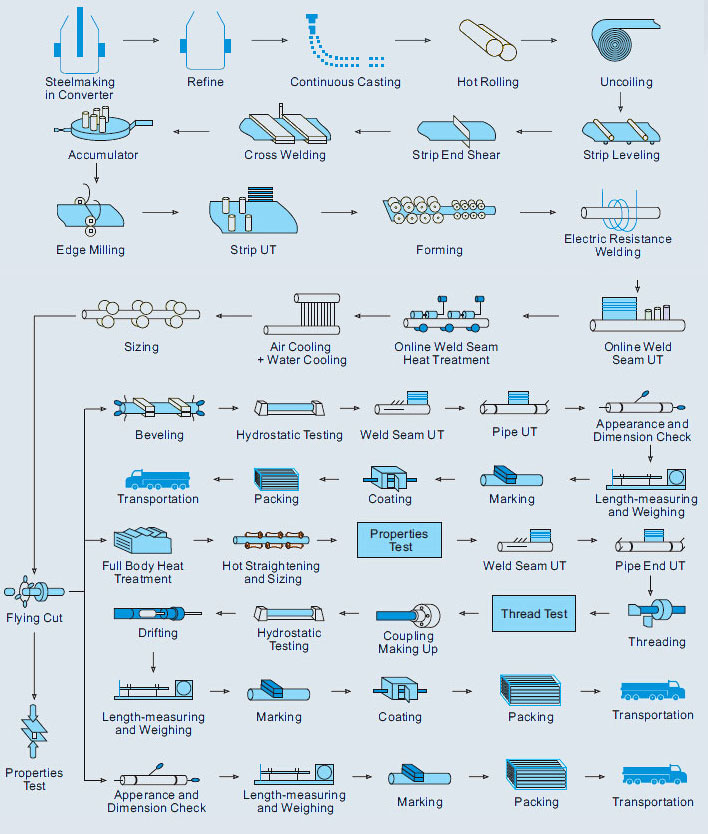

Product: ERW (Electric Resistance Welded ) Steel Pipe, ERW Carbon Steel Pipe,Mild steel pipe

Application: Used for Oil/Gas/Water transmission,Machinery Manufacturing

Size: OD: 21.3-660mm

WT: 1.0-20mm

LENGTH: 5.8/6/11.8/12m

Pipe Standard:

API 5L, ASTM A53, ASTM A178, ASTM A500/501, ASTM A691, ASTM A252, ASTM A672, EN 10217

Steel Grade:

API 5L: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

ASTM A53: GR.A, GR.B,ASTM A500 JIS G3466

EN: S275, S275JR, S355JRH, S355J2H,EN10219-1 ,EN10217-1

End: Square Ends/Plain Ends (straight cut, saw cut, torch cut),Beveled/Threaded Ends

Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE)

Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Hardness Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, NDT TEST ( ET TEST, RT TEST, UT TEST)

For ERW Line Pipe For ERW Casing

For ERW Structure Tube

For High pressure and high temperature

|

INCH

|

OD

(MM)

|

Strandard Wall Thickness

|

|||||||

|

SCH 10WT

(mm)

|

SCH 20WT

(mm)

|

SCH 40WT

(mm)

|

SCH 60WT

(mm)

|

SCH 80WT

(mm) |

SCH 100WT

(mm) |

SCH 160WT

(mm) |

XXS

(mm) |

||

|

1/4”

|

13.7

|

|

|

2.24

|

|

3.02

|

|

|

|

|

3/8”

|

17.1

|

|

|

2.31

|

|

3.2

|

|

|

|

|

1/2”

|

21.3

|

2.11

|

|

2.77

|

|

3.73

|

|

4.78

|

7.47

|

|

3/4"

|

26.7

|

2.11

|

|

2.87

|

|

3.91

|

|

5.56

|

7.82

|

|

1"

|

33.4

|

2.77

|

|

3.38

|

|

4.55

|

|

6.35

|

9.09

|

|

1-1/4"

|

42.2

|

2.77

|

|

3.56

|

|

4.85

|

|

6.35

|

9.7

|

|

1-1/2"

|

48.3

|

2.77

|

|

3.68

|

|

5.08

|

|

7.14

|

10.15

|

|

2"

|

60.3

|

2.77

|

|

3.91

|

|

5.54

|

|

8.74

|

11.07

|

|

2-1/2"

|

73

|

3.05

|

|

5.16

|

|

7.01

|

|

9.53

|

14.02

|

|

3"

|

88.9

|

3.05

|

|

5.49

|

|

7.62

|

|

11.13

|

15.24

|

|

3-1/2"

|

101.6

|

3.05

|

|

5.74

|

|

8.08

|

|

|

|

|

4"

|

114.3

|

3.05

|

4.5

|

6.02

|

|

8.56

|

|

13.49

|

17.12

|

|

5"

|

141.3

|

3.4

|

|

6.55

|

|

9.53

|

|

15.88

|

19.05

|

|

6"

|

168.3

|

3.4

|

|

7.11

|

|

10.97

|

|

18.26

|

21.95

|

|

8"

|

219.1

|

3.76

|

6.35

|

8.18

|

10.31

|

12.7

|

15.09

|

23.01

|

22.23

|

|

10"

|

273

|

4.19

|

6.35

|

9.27

|

12.7

|

15.09

|

18.26

|

28.58

|

25.4

|

|

12"

|

323.8

|

4.57

|

6.35

|

10.31

|

14.27

|

17.48

|

21.44

|

33.32

|

25.4

|

|

14"

|

355

|

6.35

|

7.92

|

11.13

|

15.09

|

19.05

|

23.83

|

36.71

|

|

|

16"

|

406

|

6.35

|

7.92

|

12.7

|

16.66

|

21.44

|

26.19

|

40.49

|

|

|

18"

|

457

|

6.35

|

7.92

|

14.27

|

19.05

|

23.83

|

29.36

|

46.24

|

|

|

20"

|

508

|

6.35

|

9.53

|

15.09

|

20.62

|

26.19

|

32.54

|

50.01

|

|

|

22"

|

559

|

6.35

|

9.53

|

|

22.23

|

28.58

|

34.93

|

54.98

|

|

|

24"

|

610

|

6.35

|

9.53

|

17.48

|

24.61

|

30.96

|

38.89

|

59.54

|

|

|

26"

|

660

|

7.92

|

12.7

|

|

|

|

|

|

|

|

28"

|

711

|

7.92

|

12.7

|

|

|

|

|

|

|

|

30"

|

762

|

7.92

|

12.7

|

|

|

|

|

|

|

|

32"

|

813

|

7.92

|

12.7

|

17.48

|

|

|

|

|

|

|

34"

|

863

|

7.92

|

12.7

|

17.48

|

|

|

|

|

|

|

36"

|

914

|

7.92

|

12.7

|

19.05

|

|

|

|

|

|

|

38"

|

965

|

|

|

|

|

|

|

|

|

|

40"

|

1016

|

|

|

|

|

|

|

|

|

|

42"

|

1066

|

|

|

|

|

|

|

|

|

|

44"

|

1117

|

|

|

|

|

|

|

|

|

|

46"

|

1168

|

|

|

|

|

|

|

|

|

|

48"

|

1219

|

|

|

|

|

|

|

|

|

Chemical Analysis and Mechanical Properties

| Chemical Analysis and Mechanical Properties | ||||||||

| Standard | Class | Grade | Chemical Analysis(%) | Mechanical Properties(min)(Mpa) | ||||

| C | Mn | P | S | Tensile Strength | Yield Strength | |||

| API 5L | PSL1 | B | 0.26 | 1.2 | 0.03 | 0.03 | 414 | 241 |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | 414 | 290 | ||

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | 434 | 317 | ||

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | 455 | 359 | ||

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | 490 | 386 | ||

| X60 | 0.26 | 1.4 | 0.03 | 0.03 | 517 | 414 | ||

| X65 | 0.26 | 1.45 | 0.03 | 0.03 | 531 | 448 | ||

| X70 | 0.26 | 1.65 | 0.03 | 0.03 | 565 | 483 | ||

| PSL2 | B | 0.22 | 1.2 | 0.025 | 0.015 | 414 | 241 | |

| X42 | 0.22 | 1.3 | 0.025 | 0.015 | 414 | 290 | ||

| X46 | 0.22 | 1.4 | 0.025 | 0.015 | 434 | 317 | ||

| X52 | 0.22 | 1.4 | 0.025 | 0.015 | 455 | 359 | ||

| X56 | 0.22 | 1.4 | 0.025 | 0.015 | 490 | 386 | ||

| X60 | 0.22 | 1.4 | 0.025 | 0.015 | 517 | 414 | ||

| X65 | 0.22 | 1.45 | 0.025 | 0.015 | 531 | 448 | ||

| X70 | 0.22 | 1.65 | 0.025 | 0.015 | 565 | 483 | ||

| X80 | 0.22 | 1.85 | 0.025 | 0.015 | 621 | 552 | ||

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!

|

INCH

|

OD

(MM)

|

Strandard Wall Thickness

|

|||||||

|

SCH 10WT

(mm)

|

SCH 20WT

(mm)

|

SCH 40WT

(mm)

|

SCH 60WT

(mm)

|

SCH 80WT

(mm) |

SCH 100WT

(mm) |

SCH 160WT

(mm) |

XXS

(mm) |

||

|

1/4”

|

13.7

|

|

|

2.24

|

|

3.02

|

|

|

|

|

3/8”

|

17.1

|

|

|

2.31

|

|

3.2

|

|

|

|

|

1/2”

|

21.3

|

2.11

|

|

2.77

|

|

3.73

|

|

4.78

|

7.47

|

|

3/4"

|

26.7

|

2.11

|

|

2.87

|

|

3.91

|

|

5.56

|

7.82

|

|

1"

|

33.4

|

2.77

|

|

3.38

|

|

4.55

|

|

6.35

|

9.09

|

|

1-1/4"

|

42.2

|

2.77

|

|

3.56

|

|

4.85

|

|

6.35

|

9.7

|

|

1-1/2"

|

48.3

|

2.77

|

|

3.68

|

|

5.08

|

|

7.14

|

10.15

|

|

2"

|

60.3

|

2.77

|

|

3.91

|

|

5.54

|

|

8.74

|

11.07

|

|

2-1/2"

|

73

|

3.05

|

|

5.16

|

|

7.01

|

|

9.53

|

14.02

|

|

3"

|

88.9

|

3.05

|

|

5.49

|

|

7.62

|

|

11.13

|

15.24

|

|

3-1/2"

|

101.6

|

3.05

|

|

5.74

|

|

8.08

|

|

|

|

|

4"

|

114.3

|

3.05

|

4.5

|

6.02

|

|

8.56

|

|

13.49

|

17.12

|

|

5"

|

141.3

|

3.4

|

|

6.55

|

|

9.53

|

|

15.88

|

19.05

|

|

6"

|

168.3

|

3.4

|

|

7.11

|

|

10.97

|

|

18.26

|

21.95

|

|

8"

|

219.1

|

3.76

|

6.35

|

8.18

|

10.31

|

12.7

|

15.09

|

23.01

|

22.23

|

|

10"

|

273

|

4.19

|

6.35

|

9.27

|

12.7

|

15.09

|

18.26

|

28.58

|

25.4

|

|

12"

|

323.8

|

4.57

|

6.35

|

10.31

|

14.27

|

17.48

|

21.44

|

33.32

|

25.4

|

|

14"

|

355

|

6.35

|

7.92

|

11.13

|

15.09

|

19.05

|

23.83

|

36.71

|

|

|

16"

|

406

|

6.35

|

7.92

|

12.7

|

16.66

|

21.44

|

26.19

|

40.49

|

|

|

18"

|

457

|

6.35

|

7.92

|

14.27

|

19.05

|

23.83

|

29.36

|

46.24

|

|

|

20"

|

508

|

6.35

|

9.53

|

15.09

|

20.62

|

26.19

|

32.54

|

50.01

|

|

|

22"

|

559

|

6.35

|

9.53

|

|

22.23

|

28.58

|

34.93

|

54.98

|

|

|

24"

|

610

|

6.35

|

9.53

|

17.48

|

24.61

|

30.96

|

38.89

|

59.54

|

|

|

26"

|

660

|

7.92

|

12.7

|

|

|

|

|

|

|

|

28"

|

711

|

7.92

|

12.7

|

|

|

|

|

|

|

|

30"

|

762

|

7.92

|

12.7

|

|

|

|

|

|

|

|

32"

|

813

|

7.92

|

12.7

|

17.48

|

|

|

|

|

|

|

34"

|

863

|

7.92

|

12.7

|

17.48

|

|

|

|

|

|

|

36"

|

914

|

7.92

|

12.7

|

19.05

|

|

|

|

|

|

|

38"

|

965

|

|

|

|

|

|

|

|

|

|

40"

|

1016

|

|

|

|

|

|

|

|

|

|

42"

|

1066

|

|

|

|

|

|

|

|

|

|

44"

|

1117

|

|

|

|

|

|

|

|

|

|

46"

|

1168

|

|

|

|

|

|

|

|

|

|

48"

|

1219

|

|

|

|

|

|

|

|

|

Chemical Analysis and Mechanical Properties

| Chemical Analysis and Mechanical Properties | ||||||||

| Standard | Class | Grade | Chemical Analysis(%) | Mechanical Properties(min)(Mpa) | ||||

| C | Mn | P | S | Tensile Strength | Yield Strength | |||

| API 5L | PSL1 | B | 0.26 | 1.2 | 0.03 | 0.03 | 414 | 241 |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | 414 | 290 | ||

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | 434 | 317 | ||

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | 455 | 359 | ||

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | 490 | 386 | ||

| X60 | 0.26 | 1.4 | 0.03 | 0.03 | 517 | 414 | ||

| X65 | 0.26 | 1.45 | 0.03 | 0.03 | 531 | 448 | ||

| X70 | 0.26 | 1.65 | 0.03 | 0.03 | 565 | 483 | ||

| PSL2 | B | 0.22 | 1.2 | 0.025 | 0.015 | 414 | 241 | |

| X42 | 0.22 | 1.3 | 0.025 | 0.015 | 414 | 290 | ||

| X46 | 0.22 | 1.4 | 0.025 | 0.015 | 434 | 317 | ||

| X52 | 0.22 | 1.4 | 0.025 | 0.015 | 455 | 359 | ||

| X56 | 0.22 | 1.4 | 0.025 | 0.015 | 490 | 386 | ||

| X60 | 0.22 | 1.4 | 0.025 | 0.015 | 517 | 414 | ||

| X65 | 0.22 | 1.45 | 0.025 | 0.015 | 531 | 448 | ||

| X70 | 0.22 | 1.65 | 0.025 | 0.015 | 565 | 483 | ||

| X80 | 0.22 | 1.85 | 0.025 | 0.015 | 621 | 552 | ||

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!