- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

Pipe Type:Galvanized steel pipe ,Hot Dip Galvanized Round Steel Pipe,Pre Galvanized Steel Pipe

Outer DiameterOD (mm):

Pre galvanized:21.3-406.4mm

Hot dipped galvanized:21.3mm-610mm

Wall Thickness (mm):

Pre galvanized:0.6-22mm

Hot dipped galvanized: 0.8- 25mm

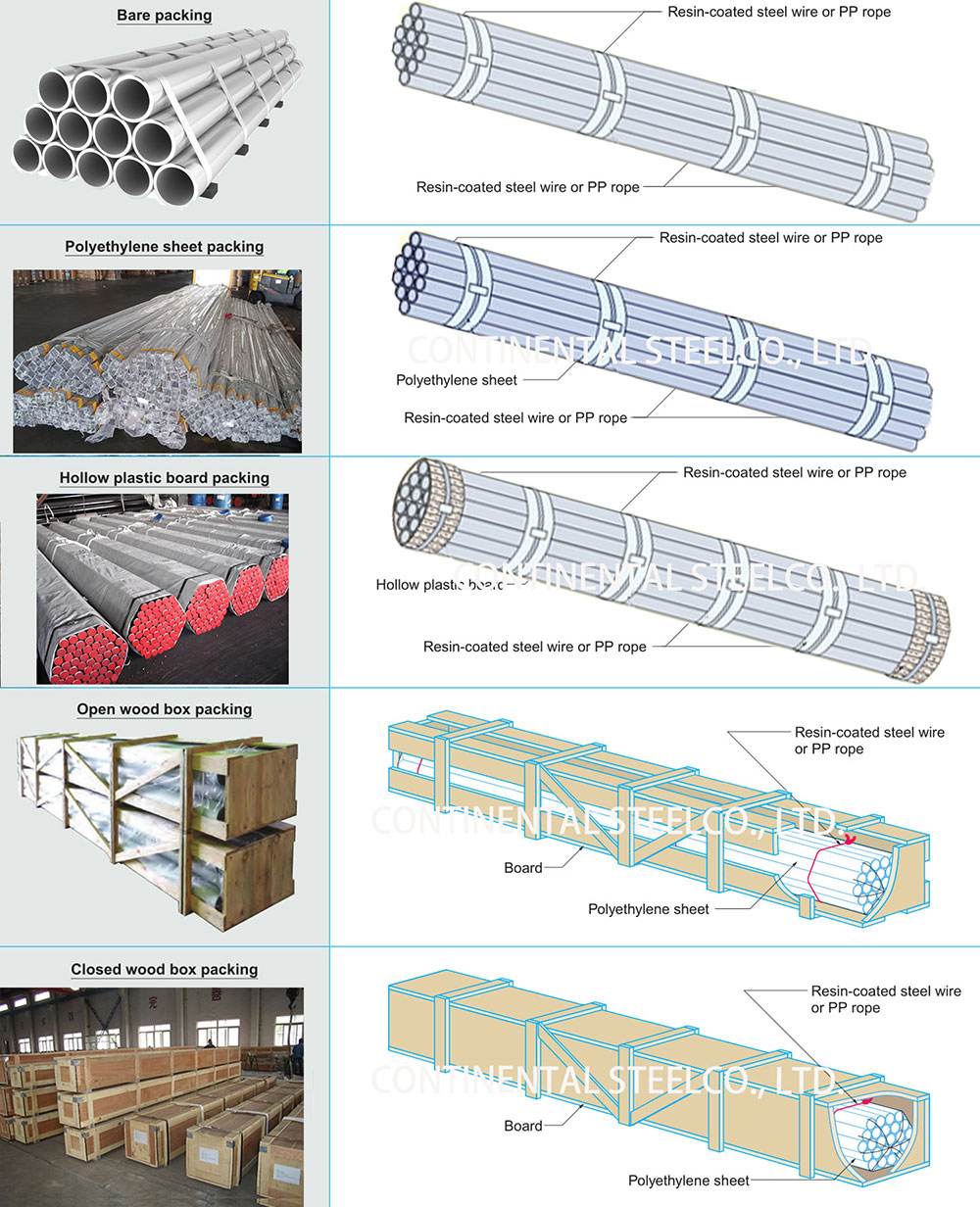

Length:LENGTH: 0.3mtr ~ 18mtr, Ramdon Length, Fixed Length, SRL, DRL

Standard and Grade:GB/T 3091 Q195/Q215/Q235/Q345, BS 1387, EN 39, EN 1139 S235JR/S275JR, ASTM A53 GR. A/B/C, JIS G3444 STK 400/STK 500,ASTM A53, EN 10025, EN 10219

Pipe Type:Seamless & Welded Steel Pipe (Round/Square/Rectangular)

End:Square Cut/Threaded, Burr Removed

Galvanizingis to make molten metal and iron matrix reaction as an alloy layer, so that the substrate and coating two combined. Galvanizing is to pickle the steel pipe first, in order to remove the iron oxide on the surface of the steel pipe. After pickling , through ammonium chloride or zinc chloride solution or ammonium chloride and zinc chloride mixed aqueous solution tank for cleaning, and then into the hot dip plating tank. Galvanizing has the advantages of uniform coating, strong adhesion and long service life. Widely used in agricultural greenhouses, fire system, gas, water supply, drainage and other fields.

Pipe Type:Seamless & Welded Steel Pipe (Round/Square/Rectangular)

End:Square Cut/Threaded, Burr Removed

Application:

1.Building and structural material

2.Mechanical and general engineering purposes

3.Manufacturing of Bus Body, Railway Boogies

4.In Telephone department as Conduit Pipes

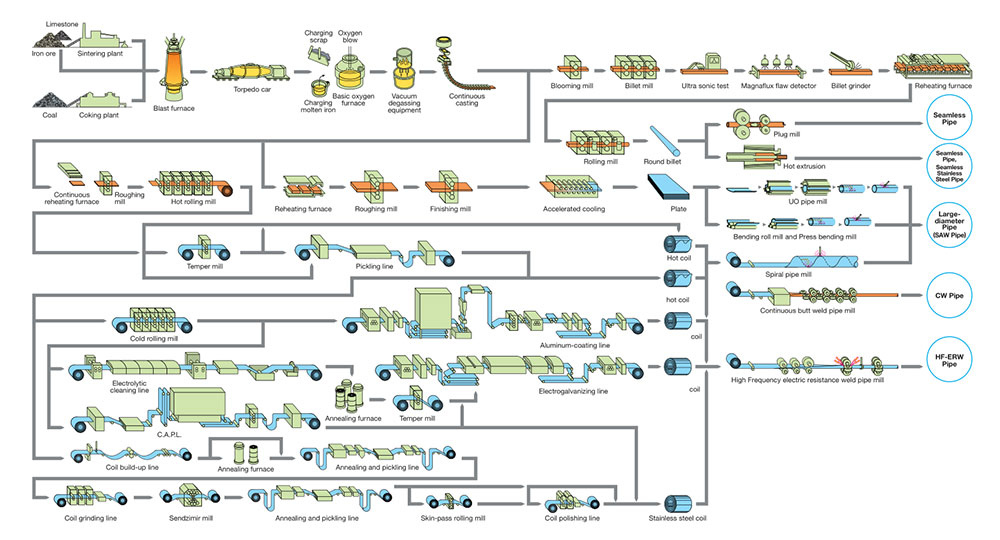

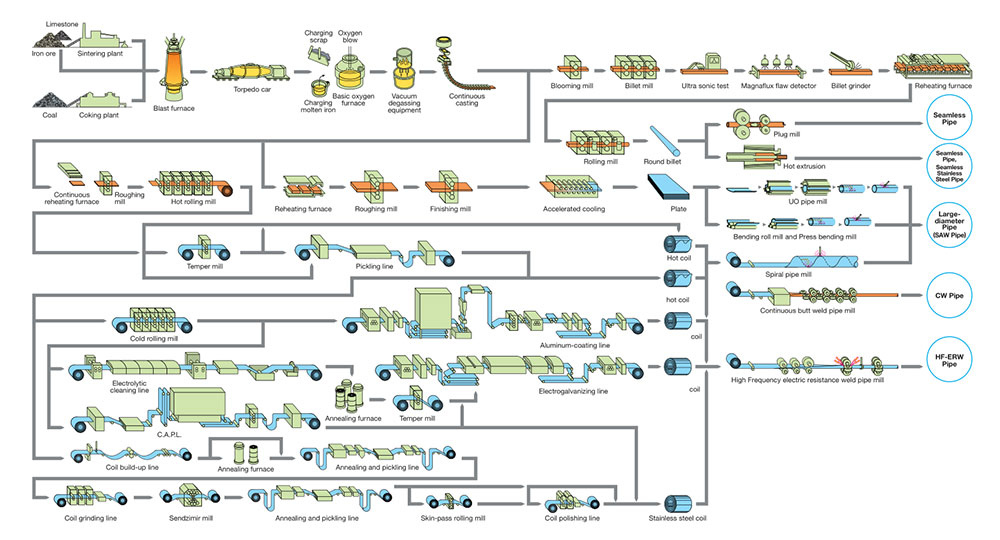

A53 Pipe Materials & Manufacture

Steel materials used to create seamless pipe and welded pipe must be produced via open hearth, electric furnace, basic oxygen, or any combination of these processes. All weld seams in electric-resistance welded A53 Grade B pipe must be heat treated after welding to a minimum of 1,000°F (540°C) to eliminate untempered martensite.

Galvanized A53 Pipe

If ordered galvanized, A53 seamless pipe must be coated inside and out via the hot-dip process. Zinc used for galvanized coatings must conform to Specification B6. The weight of this coating must not be less than 1.8 oz./ft2 (0.55 kg/m2). Test specimens for coating weight testing will be cut in approximately 4” lengths.

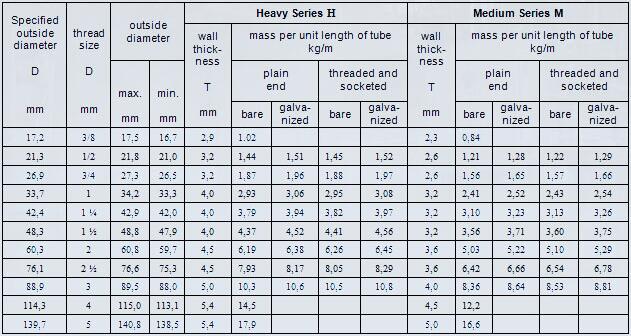

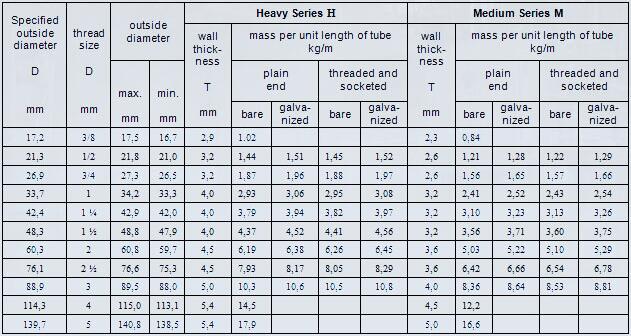

Permissible Variation in Wall Thickness

The minimum wall thickness at any point in a length of A53 steel pipe must not be more than 12.5% less than the specified wall thickness.

Permissible Variations in Outside Diameter

For ASTM A53 steel pipe NPS 1-1/2 and smaller, outside diameter must not exceed 1/64” over and 1/32” under specified diameter. For A53 pipe NPS2 and larger, outside diameter must not exceed 1% over and 1% under specified diameter.

Hydrostatic Testing of ASTM A53 Pipe

Separate hydrostatic inspection test pressures are specified for plain end, threaded, and coupled A53 steel pipe. Minimum hydrostatic test pressure for NPS 3 and under is 2,500 psi; minimum test pressure for sizes over NPS 3 is 2,800 psi. Pressure must be maintained for a minimum of 5 seconds, for all sizes.

Mechanical Testing of ASTM A53 Pipe

Electric-resistance welded ASTM A53 steel pipe of NPS 8 and larger must be transverse tested. Sending test (cold) is required for STD and XS-NPS 2 and under, and for XXS-NPS 1-1/4 and under. Flatten testing is required for NPS 2 and larger STD and XS A 53 pipe; flatten testing is not required for XXS pipe.

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!