- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

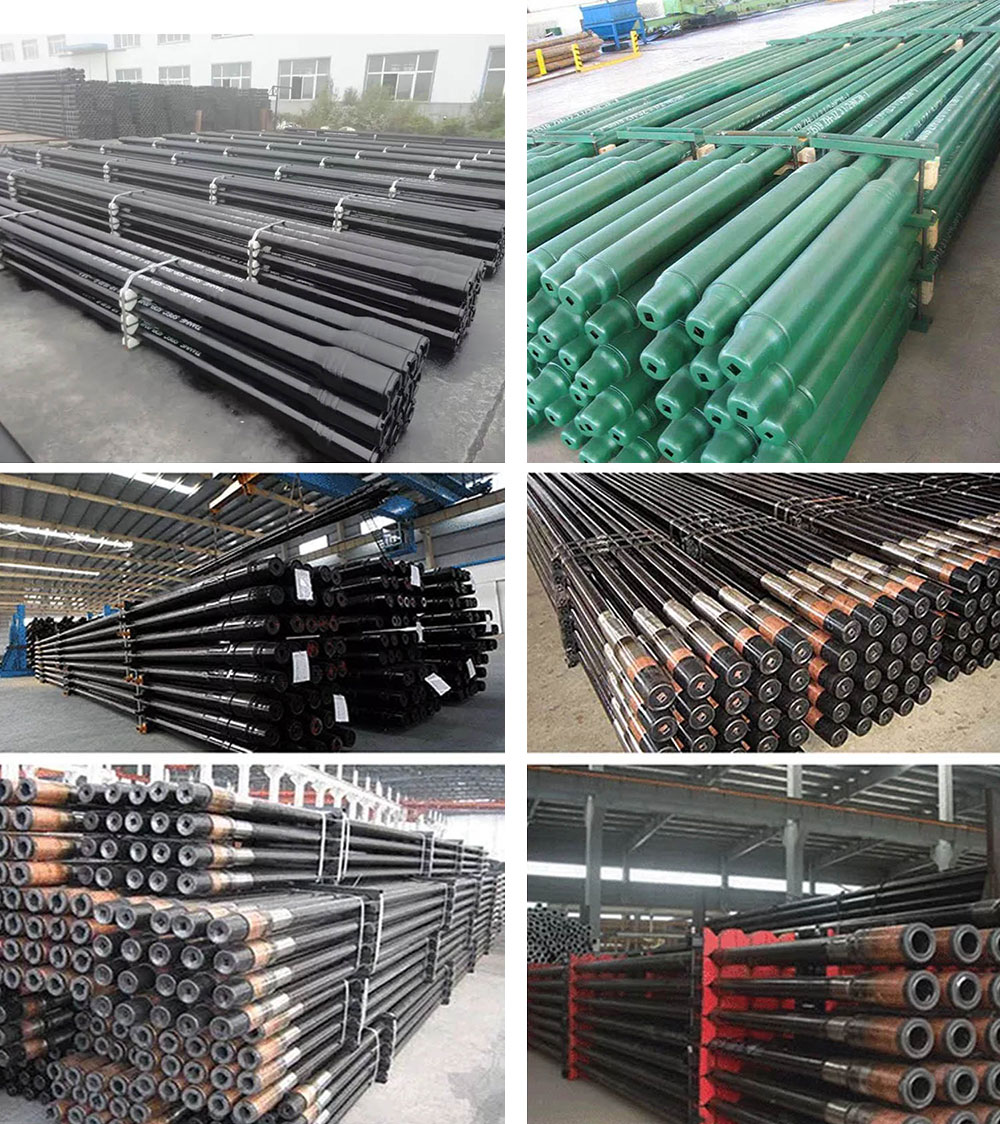

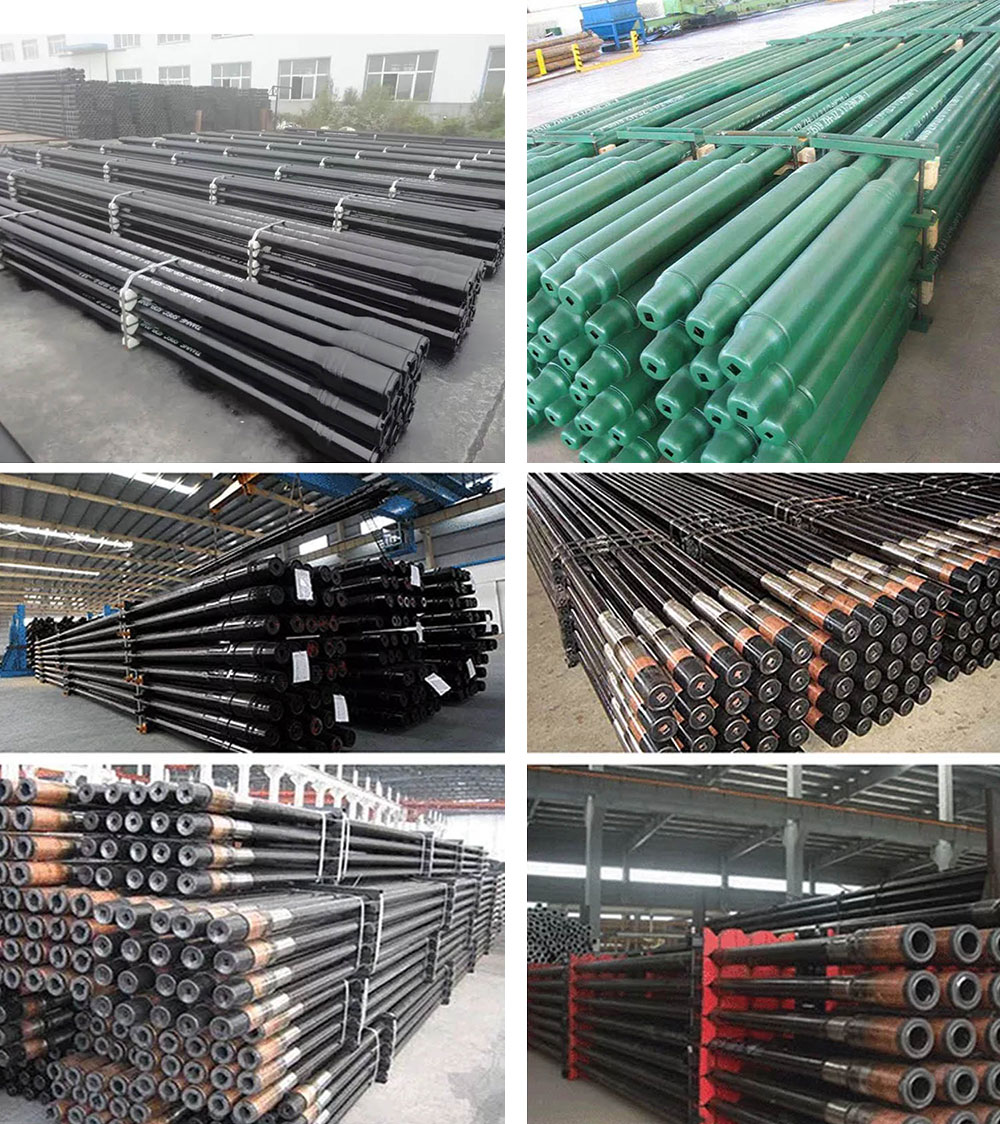

Product Name:Drill Collars ,Spiral Drill Collar,Non-magnetic Drill Collar,Drill Collar and Drill Stem Accessories;

Size:Outer diameter:3 1/8"-11"

Length :30Ft / 31Ft / 43Ft/R1~R3

Connection type:NC , REG , FH, IF

Thread:NC26, NC31, NC38, NC40, NC46, NC50, 5.1/2FH

Material:Stainless Steel/Alloy steel/4145H/Carbon steel

Standard:API 5DP/API Spec 7-1

Application:Oil and gas well drilling/Oilfield Drilling

API Oil Well Spiral Drill (Bottom) Collar for Drilling Price

1. Introduction

Drill collar is used in the drilling of oil wells for weighting drill bit, enabling it to drill through rock. It is a bar made of solid steel, either plain carbon steel or non-magnetic steel alloy, drilled lengthwise to permit the passage of drilling fluids. Drill collar is the lowest element of a drill string, which encompasses all the elements of a downhole process from surface to rock bit.

Drill collar is typically 31 feet (about 9.45 m) long and threaded at both ends, male at one end and female at the other, to allow multiple drill collars to be joined above bit assembly. The number of drill collars attached to a drill string will depend upon the material composition of the strata at drill site and the likely depth of well.

Typically, drill collars will be consistent in length but may vary in diameter, and their outside configuration may be slick or spiral. The outside diameter may vary from about 3 inches (7.62 cm) to 11 inches (27.9 cm) and greater.

2. Classification

1) Slick Drill Collar

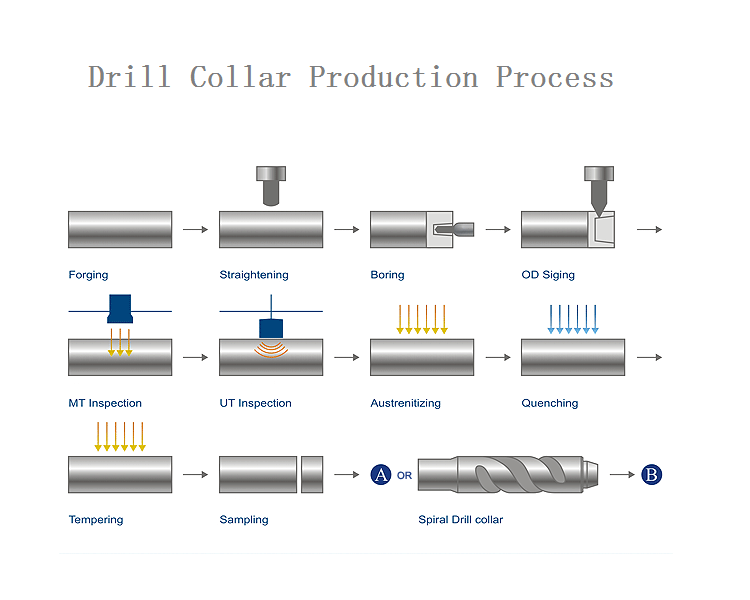

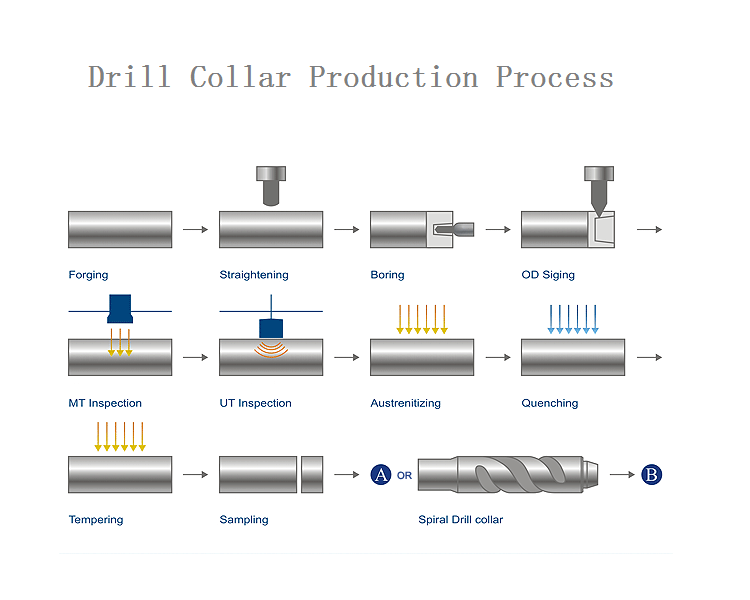

Drill Collar is an integral heavy-wall joint manufactured from a solid bar of modified alloy steel. The solid bar is quenched and tempered to obtain required mechanical properties, then trepanned, drifted and threaded. Drill collar is furnished as slick or spiraled in 30 or 31 foot lengths.

Slick drill collar is supplied with the mill as-rolled surface finish. Spiraled drill collar has grooves machined in its outside surface. The spiral grooves promote even flow of drilling fluid around collar diameter, equalizing pressure and reducing the occurrence of differential sticking.

2) Spiral Drill Collar

Spiral drill collar is used to reduce contact area with hole so as to avoid efficiently bit sticking from differential pressure. Our spiral drill collars are manufactured strictly according to API standard.

a. Materials: AISI 4145H alloy steel, non magnetic steel, etc.

b. Shape: It is a kind of drill collar which adds three dextrogyrate spiral grooves on the outer circle of ordinary drill collar when processing, to reduce the area of contact and friction with well wall, which can effectively prevent pressure sticking.

c. Usage: It is mainly used between drill head and drill pipe, so that it can make drill head work reposefully and keep right trace by providing the pressure and weight for drill head.

d. Standard: API Spec 7-1 or SY/T5144 Standard.

e. Inspection & Test: In the process of production, traceability are maintained from the receipt of raw material to the completion of final products, and serial numbers are die stamped on each work piece body. Inspection and test are performed in every manufacturing process.

3) Non-magnetic Drill Collar

The materials of non-magnetic drill collars are made from chrome manganese low carbon austenitic alloy, which has the following characteristics:

The chemical composition should be controlled strictly in the refining and forging process.

With excellent lower magnetic permeability, high strength of mechanical properties and outstanding resistant to stress corrosion cracking, and no tendency to galling.

|

Drill Collor Number*

|

Outside Diameter,

in. |

Inside Diameter,

in. |

Length,

ft |

Approximate Weight,

lb/ft |

Typical Bending

Strength Ratio |

|

NC 23-31

|

3-1/8

|

1-1/4

|

30

|

22

|

2.57:1

|

|

NC 26-35 (2-3/8 IF)

|

3-1/2

|

1-1/2

|

30

|

27

|

2.42:1

|

|

NC 31-41 (2-7/8 IF)

|

4-1/8

|

2

|

30 or 31

|

34

|

2.43:1

|

|

NC 35-47

|

4-3 /4

|

2

|

30 or 31

|

47

|

2.58:1

|

|

NC 38-50 (3-1/2 IF)

|

5

|

2-1/4

|

30 or 31

|

54

|

2.38:1

|

|

NC 44-60

|

6

|

2-1/4

|

30 or 31

|

83

|

2.49:1

|

|

NC 44-60

|

6

|

2-13 /16

|

30 or 31

|

76

|

2.84:1

|

|

NC 44-62

|

6-1/4

|

2-1/4

|

30 or 31

|

91

|

2.91:1

|

|

NC 46-62 (4 IF)

|

6-1/4

|

2-13 /16

|

30 or 31

|

84

|

2.63:1

|

|

NC 46-65 (4 IF)

|

6-1/2

|

2-1/4

|

30 or 31

|

100

|

2.76:1

|

|

NC 46-65 (4 IF)

|

6-1/2

|

2-13 /16

|

30 or 31

|

93

|

3.05:1

|

|

NC 46-67 (4 IF)

|

6-3 /4

|

2-1/4

|

30 or 31

|

109

|

3.18:1

|

|

NC 50-70 (4-1/2 IF)

|

7

|

2-1/4

|

30 or 31

|

118

|

2.54:1

|

|

NC 50-70 (4-1/2 IF)

|

7

|

2-13 /16

|

30 or 31

|

111

|

2.73:1

|

|

NC 50-72 (4-1/2 IF)

|

7-1/4

|

2-13 /16

|

30 or 31

|

120

|

3.12:1

|

|

NC 56-77

|

7-3 /4

|

2-13 /16

|

30 or 31

|

140

|

2.70:1

|

|

NC 56-80

|

8

|

2-13 /16

|

30 or 31

|

151

|

3.02:1

|

|

6-5/8 API Reg

|

8-1/4

|

2-13 /16

|

30 or 31

|

162

|

2.93:1

|

|

NC 61-90

|

9

|

2-13 /16

|

30 or 31

|

196

|

3.17:1

|

|

7-5/8 API Reg

|

9-1/2

|

3

|

30 or 31

|

217

|

2.81:1

|

|

NC 70-97

|

9-3 /4

|

3

|

30 or 31

|

230

|

2.57:1

|

|

NC 70-100

|

10

|

3

|

30 or 31

|

243

|

2.81:1

|

|

8-5/8 API Reg

|

11

|

3

|

30 or 31

|

300

|

2.84:1

|

|

O.D. |

cutting depth |

Lead ±25.4 |

||

|

mm |

in |

A(mm) |

B(mm) |

mm |

|

86 |

3.375 |

3.5±0.79 |

/ |

679 |

|

98.4 |

3.875 |

4.0±0.79 |

/ |

914 |

|

101.6~111.1 |

4~4 1/8 |

4.8±0.79 |

/ |

914 |

|

114.3~130.2 |

4 1/2~5 1/8 |

5.6±0.79 |

/ |

965 |

|

133.4~146.1 |

5 1/4~5 3/4 |

6.4±0.79 |

/ |

1067 |

|

149.2~161.9 |

5 7/8~6 3/8 |

7.1±1.59 |

/ |

1067 |

|

165.1~177.8 |

6 1/2~7 |

7.9±1.59 |

/ |

1168 |

|

181.0~200.0 |

7 1/8~7 7/8 |

8.7±1.59 |

5.6±0.79 |

1626 |

|

203.2~225.4 |

8~8 7/8 |

9.5±1.59 |

6.4±0.79 |

1727 |

|

228.6~250.8 |

9~9 7/8 |

10.3±2.37 |

7.1±1.59 |

1829 |

|

254.0~276.2 |

10~10 7/8 |

11.1±2.37 |

7.9±1.59 |

1930 |

|

279.4 |

11 |

11.9±2.37 |

8.7±1.59 |

2032 |

Typically Size of Spiral Grooving

| OD(In.) | Screw depth(In.) | Screw Leadin |

|---|---|---|

| 4~4 3/8 | 6/32±1/32 | 36±1 |

| 4 1/2~5 1/8 | 7/32±1/32 | 38±1 |

| 5 1/4~5 3/4 | 1/4±1/32 | 42±1 |

| 5 7/8~6 3/8 | 9/32±1/16 | 42±1 |

| 6 1/2~7 | 5/16±1/16 | 46±1 |

| 7 1/8~7 7/8 | 11/32±1/16 | 64±1 |

| 8~8 7/8 | 3/8±1/16 | 68±1 |

| 9~9 7/8 | 13/32±3/32 | 72±1 |

| Mechanical Performance | |||||

| OD | Yield Strength | Tensile Strength σb | Elongation | Reduction of are | Impact |

| Size | σ0.2 | Mpa(psi) | δ4% | % | Ft.1b |

| Mpa(psi) | |||||

| 3 1/8~6 3/4 | ≥758 | ≥827 | ≥18 | 50 | ≥50 |

| -110,000 | -120,000 | ||||

| 7~10 | ≥689 | ≥758 | ≥20 | ||

| -100,000 | -110,000 | ||||

|

Sreel Mark |

Chemical Composition % |

||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Cu |

Al |

|

|

4145H |

0.42~0.48 |

0.15~0.35 |

0.90~1.20 |

≤0.03 |

≤0.03 |

0.90~1.20 |

0.15~0.25 |

≤0.2 |

0.025~0.045 |

|

Other Elements:N≤0.015,Ni≤0.5 |

|||||||||

|

Size |

O.D(mm) |

I.D.(mm) |

Code |

Thread |

Length(mm) |

Weight(kg) |

|

3-1/8 |

79.4 |

31.8(1-1/4) |

NC23-31 |

NC23 |

9140 |

298 |

|

3-1/2 |

88.9 |

38.1(1-1/2) |

NC26-35 |

NC26 |

9140 |

364 |

|

4-1/8 |

104.8 |

50.8(2) |

NC31-41 |

NC31 |

9140/9450 |

474/490 |

|

4-3/4 |

120.6 |

50.8(2) |

NC35-47 |

NC35 |

9140/9450 |

674/697 |

|

5 |

127.0 |

57.2(2-1/4) |

NC38-50 |

NC38 |

9140/9450 |

725/749 |

|

6 |

152.4 |

57.2(2-1/4) |

NC44-60 |

NC44 |

9140/9450 |

1125/1163 |

|

71.4(2-13/16) |

NC44-60 |

9140/9450 |

1022/1056 |

|||

|

6-1/4 |

158.8 |

57.2(2-1/4) |

NC44-62 |

NC44 |

9140/9450 |

1237/1279 |

|

71.4(2-13/16) |

NC46-62 |

9140/9450 |

1134/1172 |

|||

|

6-1/2 |

165.1 |

57.2(2-1/4) |

NC46-65 |

NC46 |

9140/9450 |

1352/1398 |

|

71.4(2-13/16) |

NC46-65 |

NC50 |

9140/9450 |

1249/1291 |

||

|

6-3/4 |

171.4 |

57.2(2-1/4) |

NC46-67 |

NC46 |

9140/9450 |

1471/1521 |

|

7 |

177.8 |

57.2(2-1/4) |

NC50-70 |

NC50 |

9140/9450 |

1597/1651 |

|

71.4(2-13/16) |

NC50-70 |

9140/9450 |

1494/1545 |

|||

|

7-1/4 |

184.2 |

71.4(2-13/16) |

NC50-72 |

NC50 |

9140/9450 |

1625/1680 |

|

7-3/4 |

196.8 |

71.4(2-13/16) |

NC56-77 |

NC56 |

9140/9450 |

1895/1960 |

|

8 |

203.2 |

71.4(2-13/16) |

NC56-80 |

NC56/6-5/8REG |

9140/9450 |

2040/2109 |

|

8-1/4 |

209.6 |

71.4(2-13/16) |

6-5/8REG |

6-5/8REG |

9140/9450 |

2188/2263 |

|

9 |

228.6 |

71.4(2-13/16) |

NC61-90 |

NC61 |

9140/9450 |

2658/2748 |

|

9-1/2 |

241.3 |

76.2(2-13/16) |

7-5/8REG |

7-5/8REG |

9140/9450 |

2954/3054 |

|

9-3/4 |

247.6 |

76.2(3) |

NC70-97 |

NC70 |

9140/9450 |

3127/3234 |

|

10 |

254.0 |

76.2(3) |

NC70-100 |

NC70 |

9140/9450 |

3308/3421 |

|

11 |

279.4 |

76.2(3) |

8-5/8REG |

8-5/8REG |

9140/9450 |

4072/4210 |

|

Mechanical properties:<7 inch Drill Collar:Yield Strength≥758MPa,Tensile Strength≥965MPa,Four times elongation≥13%,Impact energy Ak≥54J,(Single impact work≥47J,Average≥54J)Hardness range 285HB~341HB≥7inch Drill Collar:Yield Strength≥689MPa,Tensile Strength≥931MPa,Four times elongation≥13%,Impact energy Ak≥54J,(Single impact work≥47J,Average≥54J) Hardness range 285HB~341HB |

||||||

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!

|

Drill Collor Number*

|

Outside Diameter,

in. |

Inside Diameter,

in. |

Length,

ft |

Approximate Weight,

lb/ft |

Typical Bending

Strength Ratio |

|

NC 23-31

|

3-1/8

|

1-1/4

|

30

|

22

|

2.57:1

|

|

NC 26-35 (2-3/8 IF)

|

3-1/2

|

1-1/2

|

30

|

27

|

2.42:1

|

|

NC 31-41 (2-7/8 IF)

|

4-1/8

|

2

|

30 or 31

|

34

|

2.43:1

|

|

NC 35-47

|

4-3 /4

|

2

|

30 or 31

|

47

|

2.58:1

|

|

NC 38-50 (3-1/2 IF)

|

5

|

2-1/4

|

30 or 31

|

54

|

2.38:1

|

|

NC 44-60

|

6

|

2-1/4

|

30 or 31

|

83

|

2.49:1

|

|

NC 44-60

|

6

|

2-13 /16

|

30 or 31

|

76

|

2.84:1

|

|

NC 44-62

|

6-1/4

|

2-1/4

|

30 or 31

|

91

|

2.91:1

|

|

NC 46-62 (4 IF)

|

6-1/4

|

2-13 /16

|

30 or 31

|

84

|

2.63:1

|

|

NC 46-65 (4 IF)

|

6-1/2

|

2-1/4

|

30 or 31

|

100

|

2.76:1

|

|

NC 46-65 (4 IF)

|

6-1/2

|

2-13 /16

|

30 or 31

|

93

|

3.05:1

|

|

NC 46-67 (4 IF)

|

6-3 /4

|

2-1/4

|

30 or 31

|

109

|

3.18:1

|

|

NC 50-70 (4-1/2 IF)

|

7

|

2-1/4

|

30 or 31

|

118

|

2.54:1

|

|

NC 50-70 (4-1/2 IF)

|

7

|

2-13 /16

|

30 or 31

|

111

|

2.73:1

|

|

NC 50-72 (4-1/2 IF)

|

7-1/4

|

2-13 /16

|

30 or 31

|

120

|

3.12:1

|

|

NC 56-77

|

7-3 /4

|

2-13 /16

|

30 or 31

|

140

|

2.70:1

|

|

NC 56-80

|

8

|

2-13 /16

|

30 or 31

|

151

|

3.02:1

|

|

6-5/8 API Reg

|

8-1/4

|

2-13 /16

|

30 or 31

|

162

|

2.93:1

|

|

NC 61-90

|

9

|

2-13 /16

|

30 or 31

|

196

|

3.17:1

|

|

7-5/8 API Reg

|

9-1/2

|

3

|

30 or 31

|

217

|

2.81:1

|

|

NC 70-97

|

9-3 /4

|

3

|

30 or 31

|

230

|

2.57:1

|

|

NC 70-100

|

10

|

3

|

30 or 31

|

243

|

2.81:1

|

|

8-5/8 API Reg

|

11

|

3

|

30 or 31

|

300

|

2.84:1

|

|

O.D. |

cutting depth |

Lead ±25.4 |

||

|

mm |

in |

A(mm) |

B(mm) |

mm |

|

86 |

3.375 |

3.5±0.79 |

/ |

679 |

|

98.4 |

3.875 |

4.0±0.79 |

/ |

914 |

|

101.6~111.1 |

4~4 1/8 |

4.8±0.79 |

/ |

914 |

|

114.3~130.2 |

4 1/2~5 1/8 |

5.6±0.79 |

/ |

965 |

|

133.4~146.1 |

5 1/4~5 3/4 |

6.4±0.79 |

/ |

1067 |

|

149.2~161.9 |

5 7/8~6 3/8 |

7.1±1.59 |

/ |

1067 |

|

165.1~177.8 |

6 1/2~7 |

7.9±1.59 |

/ |

1168 |

|

181.0~200.0 |

7 1/8~7 7/8 |

8.7±1.59 |

5.6±0.79 |

1626 |

|

203.2~225.4 |

8~8 7/8 |

9.5±1.59 |

6.4±0.79 |

1727 |

|

228.6~250.8 |

9~9 7/8 |

10.3±2.37 |

7.1±1.59 |

1829 |

|

254.0~276.2 |

10~10 7/8 |

11.1±2.37 |

7.9±1.59 |

1930 |

|

279.4 |

11 |

11.9±2.37 |

8.7±1.59 |

2032 |

Typically Size of Spiral Grooving

| OD(In.) | Screw depth(In.) | Screw Leadin |

|---|---|---|

| 4~4 3/8 | 6/32±1/32 | 36±1 |

| 4 1/2~5 1/8 | 7/32±1/32 | 38±1 |

| 5 1/4~5 3/4 | 1/4±1/32 | 42±1 |

| 5 7/8~6 3/8 | 9/32±1/16 | 42±1 |

| 6 1/2~7 | 5/16±1/16 | 46±1 |

| 7 1/8~7 7/8 | 11/32±1/16 | 64±1 |

| 8~8 7/8 | 3/8±1/16 | 68±1 |

| 9~9 7/8 | 13/32±3/32 | 72±1 |

| Mechanical Performance | |||||

| OD | Yield Strength | Tensile Strength σb | Elongation | Reduction of are | Impact |

| Size | σ0.2 | Mpa(psi) | δ4% | % | Ft.1b |

| Mpa(psi) | |||||

| 3 1/8~6 3/4 | ≥758 | ≥827 | ≥18 | 50 | ≥50 |

| -110,000 | -120,000 | ||||

| 7~10 | ≥689 | ≥758 | ≥20 | ||

| -100,000 | -110,000 | ||||

|

Sreel Mark |

Chemical Composition % |

||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Cu |

Al |

|

|

4145H |

0.42~0.48 |

0.15~0.35 |

0.90~1.20 |

≤0.03 |

≤0.03 |

0.90~1.20 |

0.15~0.25 |

≤0.2 |

0.025~0.045 |

|

Other Elements:N≤0.015,Ni≤0.5 |

|||||||||

|

Size |

O.D(mm) |

I.D.(mm) |

Code |

Thread |

Length(mm) |

Weight(kg) |

|

3-1/8 |

79.4 |

31.8(1-1/4) |

NC23-31 |

NC23 |

9140 |

298 |

|

3-1/2 |

88.9 |

38.1(1-1/2) |

NC26-35 |

NC26 |

9140 |

364 |

|

4-1/8 |

104.8 |

50.8(2) |

NC31-41 |

NC31 |

9140/9450 |

474/490 |

|

4-3/4 |

120.6 |

50.8(2) |

NC35-47 |

NC35 |

9140/9450 |

674/697 |

|

5 |

127.0 |

57.2(2-1/4) |

NC38-50 |

NC38 |

9140/9450 |

725/749 |

|

6 |

152.4 |

57.2(2-1/4) |

NC44-60 |

NC44 |

9140/9450 |

1125/1163 |

|

71.4(2-13/16) |

NC44-60 |

9140/9450 |

1022/1056 |

|||

|

6-1/4 |

158.8 |

57.2(2-1/4) |

NC44-62 |

NC44 |

9140/9450 |

1237/1279 |

|

71.4(2-13/16) |

NC46-62 |

9140/9450 |

1134/1172 |

|||

|

6-1/2 |

165.1 |

57.2(2-1/4) |

NC46-65 |

NC46 |

9140/9450 |

1352/1398 |

|

71.4(2-13/16) |

NC46-65 |

NC50 |

9140/9450 |

1249/1291 |

||

|

6-3/4 |

171.4 |

57.2(2-1/4) |

NC46-67 |

NC46 |

9140/9450 |

1471/1521 |

|

7 |

177.8 |

57.2(2-1/4) |

NC50-70 |

NC50 |

9140/9450 |

1597/1651 |

|

71.4(2-13/16) |

NC50-70 |

9140/9450 |

1494/1545 |

|||

|

7-1/4 |

184.2 |

71.4(2-13/16) |

NC50-72 |

NC50 |

9140/9450 |

1625/1680 |

|

7-3/4 |

196.8 |

71.4(2-13/16) |

NC56-77 |

NC56 |

9140/9450 |

1895/1960 |

|

8 |

203.2 |

71.4(2-13/16) |

NC56-80 |

NC56/6-5/8REG |

9140/9450 |

2040/2109 |

|

8-1/4 |

209.6 |

71.4(2-13/16) |

6-5/8REG |

6-5/8REG |

9140/9450 |

2188/2263 |

|

9 |

228.6 |

71.4(2-13/16) |

NC61-90 |

NC61 |

9140/9450 |

2658/2748 |

|

9-1/2 |

241.3 |

76.2(2-13/16) |

7-5/8REG |

7-5/8REG |

9140/9450 |

2954/3054 |

|

9-3/4 |

247.6 |

76.2(3) |

NC70-97 |

NC70 |

9140/9450 |

3127/3234 |

|

10 |

254.0 |

76.2(3) |

NC70-100 |

NC70 |

9140/9450 |

3308/3421 |

|

11 |

279.4 |

76.2(3) |

8-5/8REG |

8-5/8REG |

9140/9450 |

4072/4210 |

|

Mechanical properties:<7 inch Drill Collar:Yield Strength≥758MPa,Tensile Strength≥965MPa,Four times elongation≥13%,Impact energy Ak≥54J,(Single impact work≥47J,Average≥54J)Hardness range 285HB~341HB≥7inch Drill Collar:Yield Strength≥689MPa,Tensile Strength≥931MPa,Four times elongation≥13%,Impact energy Ak≥54J,(Single impact work≥47J,Average≥54J) Hardness range 285HB~341HB |

||||||

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!