- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

Pipe Type:U Shape Steel Bending Tube Stainless Steel Tube/Pipe Bending U Tube

Products Details

| Available U-bent Tubes | ||||||

| Products |

Dimensions (mm) O.D. |

W.T. | Length | Standards | Materials | Remarks |

|

U-bent Tubes for Heat Exchanger |

12.7-76.2mm (1/2"-3") |

0.5-5.16mm (0.02"-0.203") |

Leg Length: 15.24m(50') Total length: 32.00m(105') |

ASTM/ASME A/SA213 |

T5,T11,T12,T22, T9,T91, TP304/304L, TP304H, TP316/316L, TP347/347H, TP316Ti, TP321/321H, TP310S |

Seamless ferritic and Austenitic Stainless Steel U-bent Tubes |

|

ASTM/ASME A/SA249 |

TP304,TP304L, TP316,TP316L... |

Welded Stainless Steel U-bent Tubes |

||||

|

ASTM/ASME A/SA789 |

UNS S31803/32205, UNS S32750... |

Duplex Stainless Steel U-bent Tubes |

||||

|

ASTM/ASME A/SA163 |

Monel400, UNS N06600,625, Incoloy800/800H, 825... |

Ferritic and Martensitic Stainless Steel Seamless U-bent Tubes |

||||

|

Seamless and (Welded) Re-drawn Stainless Steel Feed Water Heater U-bent Tubes |

12.7-25.4mm (1/2"-1") |

0.7-3.05mm (0.028"-0.12") |

Leg Length: 15.24m(50') Total length: 32.00m(105') |

ASTM/ASME A/SA688/213 ASTM/ASME A/SA803 |

TP304,TP304L, TP304LN, TP316,TP316L. TP316LN,TP439... |

Feed Water Heater Tubes for Thermal Power Station |

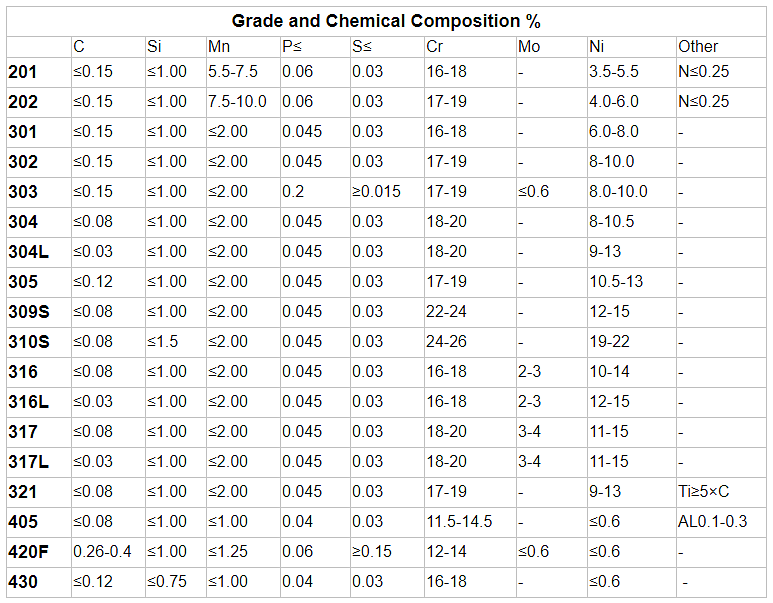

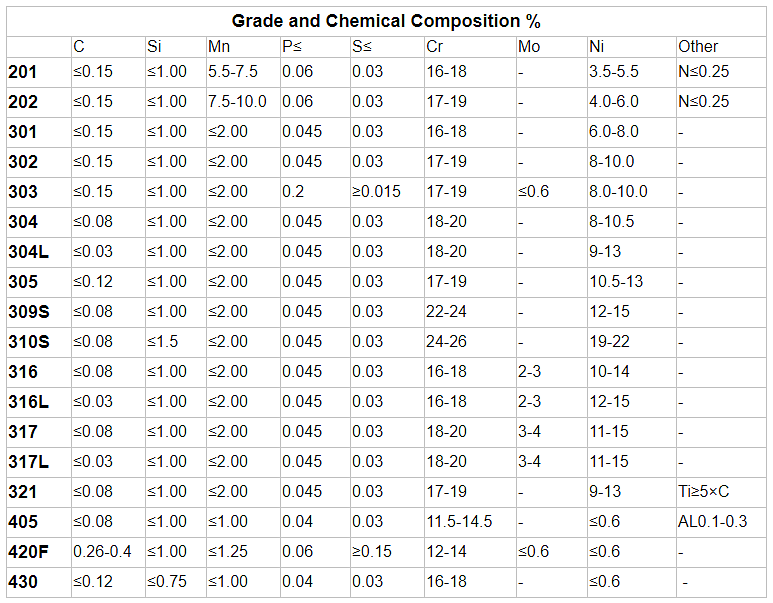

| Elem-Ent | Grade | TP304 | TP304L | TP304LN | TP316 | TP316L | TP316LN | TP XM-29 | TP 304N | TP 316N |

| % | UNS | S30400 | S30403 | S30453 | S31600 | S31603 | S31653 | S24000 | S30451 | S31651 |

| C, Max | 0.08 | 0.035 | 0.035 | 0.08 | 0.035 | 0.035 | 0.060 | 0.08 | 0.08 | |

| Mn, Max | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 11.50-14.50 | 2.00 | 2.00 | |

| Ph, Max | 0.040 | 0.040 | 0.040 | 0.040 | 0.040 | 0.040 | 0.060 | 0.040 | 0.040 | |

| S, Max | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | |

| Si,,Max | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 1.00 | 0.75 | 0.75 | |

| Ni | 8.00-11.00 | 8.00-13.00 | 8.00-13.00 | 10.00-14.00 | 10.00-15.00 | 10.00-15.00 | 2.25-3.75 | 8.00-1.00 | 10.00-14.00 | |

| Cr | 18.00-20.00 | 18.00-20.00 | 18.00-20.00 | 16.00-18.00 | 16.00-18.00 | 16.00-18.00 | 17.00-19.00 | 18.00-20.00 | 16.00-18.00 | |

| Mo | - | - | - | 2.00-3.00 | 2.00-3.00 | 2.00-3.00 | - | - | 2.00-3.00 | |

| N | - | - | 0.10-0.16 | - | - | 0.10-0.16 | 0.20-0.40 | 0.10-0.16 | 0.10-0.16 |

ASTM A688 U bend tube tolerance of outside should be accordance with specification A1016/M, bent portion of U tubes for R =2 X D or greater, tolerance shall deviate from the nominal diameter prior to bending by more than 10 %, if less than 2 X D is specified, tolerances could be greater, minimum wall thickness shall not exceed +20 % − 0, average wall thickness are 10 % of the nominal wall thickness, bent area wall tolerance shall not be less than value determined by the equation: 4RT/(4R+D).

| Leg Length, Ft (M) | Plus Tolerance, In (Mm) |

|---|---|

| <= 20 (6) | 1/8 (3.2) |

| >20(6), <=30(9) | 5/32 (4.0) |

| >30 (9), <=40 (12.2) | 3/16 (4.8) |

| Tube OD, In, (Mm) | Tolerance, In, (Mm) |

|---|---|

| <=5.8 (15.9) | 0.010 (0.25) |

| >5.8 (15.9), <=1 (25.4) | 0.016 (0.4) |

Compared to ASTM A249/A268 specification, ASTM A688 requires more and specific tests to ensure high quality tube, and more tighter tolerances.

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!

| Elem-Ent | Grade | TP304 | TP304L | TP304LN | TP316 | TP316L | TP316LN | TP XM-29 | TP 304N | TP 316N |

| % | UNS | S30400 | S30403 | S30453 | S31600 | S31603 | S31653 | S24000 | S30451 | S31651 |

| C, Max | 0.08 | 0.035 | 0.035 | 0.08 | 0.035 | 0.035 | 0.060 | 0.08 | 0.08 | |

| Mn, Max | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 11.50-14.50 | 2.00 | 2.00 | |

| Ph, Max | 0.040 | 0.040 | 0.040 | 0.040 | 0.040 | 0.040 | 0.060 | 0.040 | 0.040 | |

| S, Max | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | |

| Si,,Max | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 1.00 | 0.75 | 0.75 | |

| Ni | 8.00-11.00 | 8.00-13.00 | 8.00-13.00 | 10.00-14.00 | 10.00-15.00 | 10.00-15.00 | 2.25-3.75 | 8.00-1.00 | 10.00-14.00 | |

| Cr | 18.00-20.00 | 18.00-20.00 | 18.00-20.00 | 16.00-18.00 | 16.00-18.00 | 16.00-18.00 | 17.00-19.00 | 18.00-20.00 | 16.00-18.00 | |

| Mo | - | - | - | 2.00-3.00 | 2.00-3.00 | 2.00-3.00 | - | - | 2.00-3.00 | |

| N | - | - | 0.10-0.16 | - | - | 0.10-0.16 | 0.20-0.40 | 0.10-0.16 | 0.10-0.16 |

ASTM A688 U bend tube tolerance of outside should be accordance with specification A1016/M, bent portion of U tubes for R =2 X D or greater, tolerance shall deviate from the nominal diameter prior to bending by more than 10 %, if less than 2 X D is specified, tolerances could be greater, minimum wall thickness shall not exceed +20 % − 0, average wall thickness are 10 % of the nominal wall thickness, bent area wall tolerance shall not be less than value determined by the equation: 4RT/(4R+D).

| Leg Length, Ft (M) | Plus Tolerance, In (Mm) |

|---|---|

| <= 20 (6) | 1/8 (3.2) |

| >20(6), <=30(9) | 5/32 (4.0) |

| >30 (9), <=40 (12.2) | 3/16 (4.8) |

| Tube OD, In, (Mm) | Tolerance, In, (Mm) |

|---|---|

| <=5.8 (15.9) | 0.010 (0.25) |

| >5.8 (15.9), <=1 (25.4) | 0.016 (0.4) |

Compared to ASTM A249/A268 specification, ASTM A688 requires more and specific tests to ensure high quality tube, and more tighter tolerances.

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!