- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

Product Type:Aluminum steel Sheet / Plate

Thickness: 0.20mm - 500mm

Width: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm,3800mm etc

Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Length:1000mm - 12000mm

Temper: O,H14,H24,H32,H112 Etc;T4,T651 Etc

Material :

1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc.

2000 Series: 2014, 2024, etc.

3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc.

4000 Series: 4045, 4047, 4343, etc.

5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5454, 5754, 5A06, etc.f

6000 Series: 6061, 6063, 6082, 6A02, etc.

Surface Finishing : Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

Specifications

| 1000 Series | Industrial Pure Aluminum(1A99, 1A97, 1050, 1050A, 1A50, 1060, 1070, 1350, 1145, 1035, 1100, 1200, 1235, 1A30) |

| 2000 Series | Aluminum-copper Alloys(2A01, 2A02, 2A04, 2A06, 2A11, 2A12, 2A14, 2A16, 2A17, 2A21, 2A25, 2A70, 2A80, 2A90, 2204, 2014, 2214, 2017, 2219, 2024, 2124) |

| 3000 Series | Aluminum-manganese Alloys(3A21, 3003, 3103, 3004, 3005, 3105) |

| 4000 Series | Al-Si Alloys(4A03, 4A11, 4A13, 4A17, 4004, 4032, 4043, 4043A, 4047, 4047A) |

| 5000 Series | Al-Mg Alloys(5A01, 5A03, 5A05, 5A06, 5B05, 5B06, 5A12, 5A13, 5A30, 5A66, 5005, 5019, 5050, 5251, 5052, 5154, 5454, 5754, 5056, 5456, 5082, 5083, 5182, 5183, In 5086) |

| 6000 Series | Aluminum Magnesium Silicon Alloys(6A12, 6B12, 6A51, 6101, 6005, 6060, 6061, 6063, 6063A, 6181, 6082) |

| 7000 Series | Aluminum, Zinc, Magnesium and Copper Alloys(7003, 7005, 7020, 7022, 7050, 7075, 7475, 7A01, 7A03, 7A04, 7A05, 7A09, 7A10, 7A15, 7A52) |

| 8000 Series | Other Alloys(8A06, 8011, 8090) |

Aluminum Grade

| Product name | Aluminum Sheet:0.15-6.0 Aluminum Plate:6.0-25.0 |

| Width(mm) | 20-2000mm or customized according to requirements |

| Thickness | 0.35mm-100mm or customized according to requirements |

| Length | According to the need to customize |

| Standard | GB, JIS, DIN, ASTM,ANSI |

| Surface treatment | Bright, polished, hairline, brush, sandblasting, grid, relief, etching, rolling surface finish, no stains, no rough edges, patterns, printing,brushed, mirror, embossed, sandblasted, etc |

| Temper | O, H12, H14, H16, H18, H112, H113, H19, H111, H22, H24, H26, H211, H32, H36, H38, H131, H151, H241, H261, H341, H361, F, T53, T6, T63, T6351, T651, T73, T7351, etc. |

| Type | Plate, sheet,strips,belt, thin plate, medium plate, thick plate, super thick plate, coil |

| Properties | Corrosion resistance, heat resistance, high hardness, good ductility |

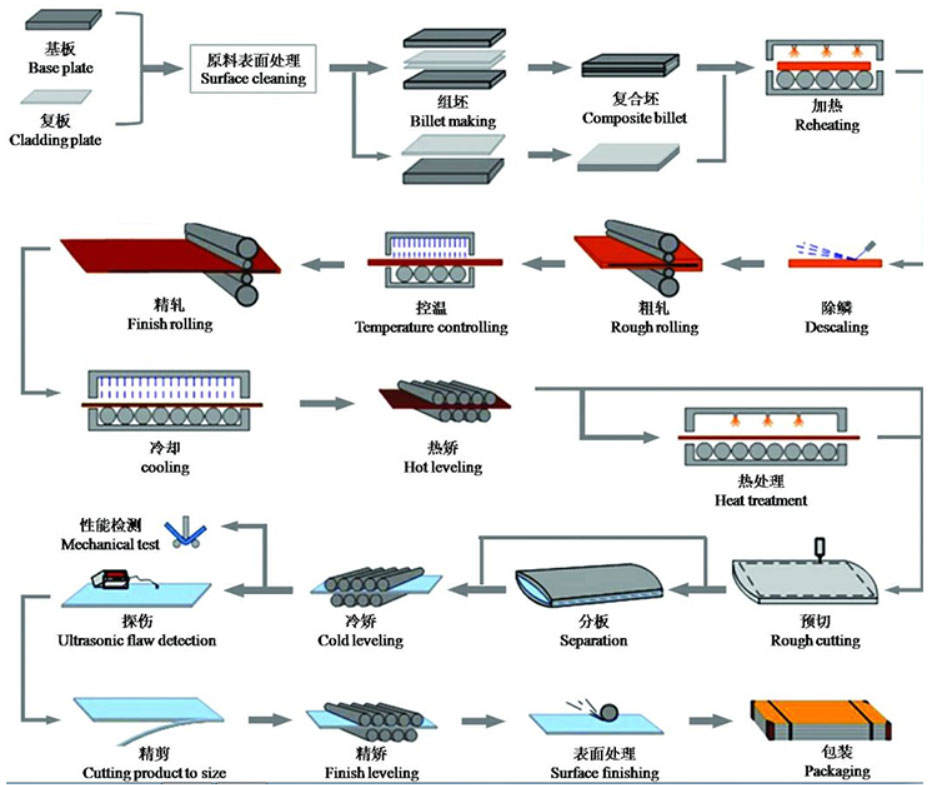

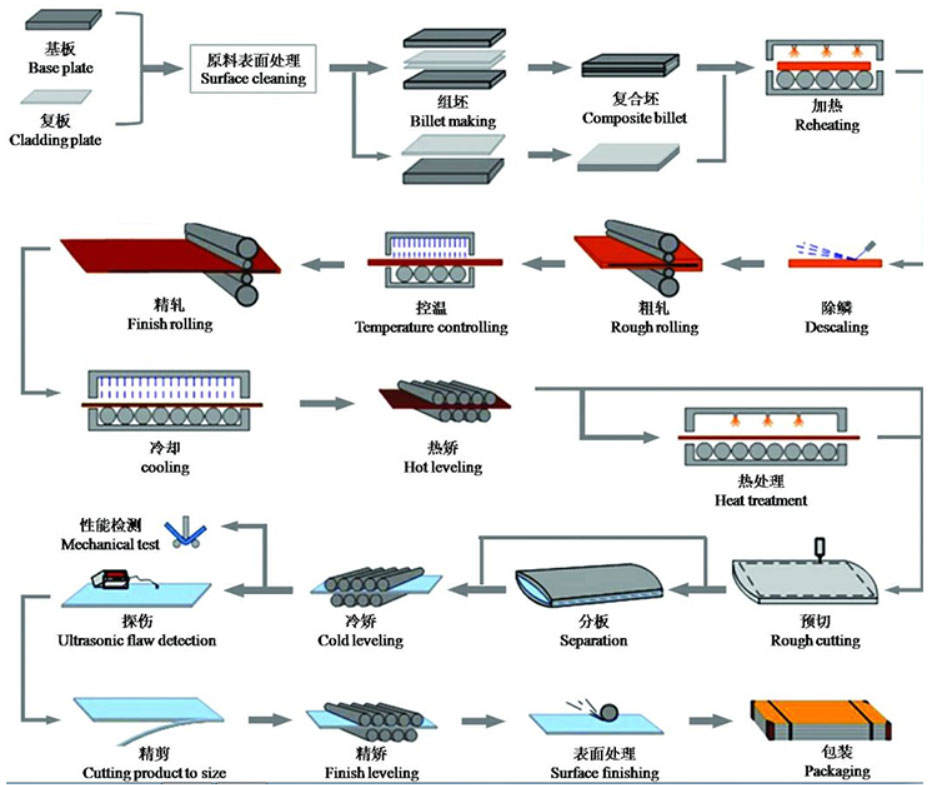

| Production process | Hot rolling or cold rolling |

| Product application | Industry, transportation, building modeling, automobile, medical machinery, etc |

| Package | Standard export package, such as wooden box or as required. |

Mechanical properties

|

Aluminum Alloy |

Alloy State |

Thickness(mm) |

Tensile strength (Rm/Mpa) |

Yield strength (Rp0.2/Mpa) |

Elongation (%) |

Bending radius(α) |

Hardness( HBW)α |

||

|

A50mm |

A5.65 |

90° |

180° |

||||||

|

≥ |

|

||||||||

|

5754 |

F |

≥2.5~100 |

— |

— |

— |

— |

— |

— |

— |

|

>100.0~150.0 |

180 |

— |

— |

— |

— |

— |

— |

||

|

O |

>0.2~0.5 |

190~240 |

80 |

12 |

— |

0t |

0.5t |

38 |

|

|

>0.5~1.5 |

190~240 |

80 |

14 |

— |

0.5t |

0.5t |

38 |

||

|

>1.5~3.0 |

190~240 |

80 |

16 |

— |

1.0t |

1.0t |

38 |

||

|

>3.0~6.0 |

190~240 |

80 |

18 |

— |

1.0t |

1.0t |

38 |

||

|

>6.0~12.5 |

190~240 |

80 |

18 |

— |

2.0t |

— |

38 |

||

|

>12.5~100.0 |

190~240 |

80 |

— |

17 |

— |

— |

38 |

||

|

H112 |

>6.0~12.5 |

190 |

100 |

12 |

— |

— |

— |

62 |

|

|

>12.5~25.0 |

190 |

90 |

— |

10 |

— |

— |

58 |

||

|

>25.0~40.0 |

190 |

80 |

— |

12 |

— |

— |

52 |

||

|

>40.0~80.0 |

190 |

80 |

— |

14 |

— |

— |

52 |

||

|

H12 |

>0.2~0.5 |

220~270 |

170 |

4 |

— |

— |

— |

46 |

|

|

>0.5~1.5 |

220~270 |

170 |

5 |

— |

— |

— |

46 |

||

|

>1.5~3.0 |

220~270 |

170 |

6 |

— |

— |

— |

46 |

||

|

>3.0~6.0 |

220~270 |

170 |

7 |

— |

— |

— |

46 |

||

|

H14 |

>0.2~0.5 |

240~280 |

190 |

3 |

— |

— |

— |

54 |

|

|

>0.5~1.5 |

240~280 |

190 |

3 |

— |

— |

— |

60 |

||

|

>1.5~3.0 |

240~280 |

190 |

4 |

— |

— |

— |

60 |

||

|

>3.0~6.0 |

240~280 |

190 |

4 |

— |

— |

— |

60 |

||

Physical and chemical properties of product grade

1000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others: |

Others: |

Al: Min. |

|

Each |

Total |

||||||||||

|

1050 |

0.25 |

0.4 |

0.05 |

0.05 |

0.05 |

– |

0.05 |

0.03 |

0.03 |

– |

99.5 |

|

1050A |

0.25 |

0.4 |

0.05 |

0.05 |

0.05 |

– |

0.07 |

0.05 |

0.03 |

– |

99.5 |

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

– |

0.05 |

0.03 |

0.03 |

– |

99.6 |

|

1070 |

0.2 |

0.25 |

0.04 |

0.03 |

0.03 |

– |

0.04 |

0.03 |

0.03 |

– |

99.7 |

|

1100 |

0.95 Si + Fe |

0.05~0.20 |

0.05 |

– |

– |

0.1 |

– |

0.05 |

0.15 |

99 |

|

2000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al:Min. |

|

2A06 |

0.5 |

0.5 |

3.8-4.3 |

0.5-1.0 |

1.7-2.3 |

– |

0.1 |

0.03-0.15 |

the rest part |

|

2A16 |

0.3 |

0.3 |

6.0-7.0 |

0.4-0.8 |

0.05 |

– |

0.1 |

0.1-0.2 |

the rest part |

3000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al: Min. |

|

3003 |

0.6 |

0.7 |

0.05~0.20 |

1.0~ 1.5 |

— |

— |

0.1 |

— |

the rest part |

|

3004 |

0.3 |

0.7 |

0.25 |

1.0~ 1.5 |

0.8–1.3 |

— |

0.25 |

— |

the rest part |

|

3A21 |

0.6 |

0.7 |

0.05~0.20 |

1.0~ 1.5 |

— |

— |

0.1 |

— |

the rest part |

5000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other |

Al: Min. |

|

5052 |

≤0.25 |

≤0.40 |

≤0.10 |

≤0.10 |

2.2-2.8 |

0.15-0.35 |

≤ 0.1 |

/ |

≤ 0.05 |

the rest part |

|

5005 |

≤ 0.3 |

≤ 0.7 |

≤ 0.2 |

≤ 0.2 |

0.5 - 1.1 |

≤ 0.1 |

0.25 |

/ |

≤ 0.05 |

the rest part |

|

5083 |

≤ 0.4 |

≤0.40 |

≤0.10 |

0.4-1.0 |

4.0-4.9 |

0.05-0.25 |

≤ 0.25 |

/ |

≤ 0.05 |

the rest part |

|

5A05 |

≤ 0.5 |

≤0.50 |

≤0.10 |

0.3-0.6 |

4.8-5.5 |

/ |

≤ 0.20 |

/ |

≤ 0.05 |

the rest part |

6000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other |

Al: Min. |

|

6061 |

0.4-0.8 |

≤0.7 |

0.15-0.4 |

≤0.15 |

0.8-1.2 |

0.04-0.35 |

≤0.25 |

≤0.15 |

≤0.05 |

The rest part |

7000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other |

Al: Min. |

|

7075 |

≤0.4 |

≤0.5 |

1.2-2.0 |

≤0.30 |

2.1-2.9 |

0.18-0.28 |

5.1-6.1 |

≤0.2 |

≤0.05 |

the rest part |

8000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other |

Al: Min. |

|

8011 |

0.5-0.9 |

0.6-1 |

≤0.1 |

≤0.2 |

≤0.05 |

≤0.05 |

≤0.10 |

≤0.08 |

≤0.05 |

The rest part |

Mechanical properties

|

Aluminum Alloy |

Alloy State |

Thickness(mm) |

Tensile strength (Rm/Mpa) |

Yield strength (Rp0.2/Mpa) |

Elongation (%) |

|

5A05 |

O、H112 |

0.15-500 |

≥225 |

≥110 |

≥1 |

We can make all kinds of conventional aluminum plate and special specification aluminum plate according to the need.

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!

Specifications

| 1000 Series | Industrial Pure Aluminum(1A99, 1A97, 1050, 1050A, 1A50, 1060, 1070, 1350, 1145, 1035, 1100, 1200, 1235, 1A30) |

| 2000 Series | Aluminum-copper Alloys(2A01, 2A02, 2A04, 2A06, 2A11, 2A12, 2A14, 2A16, 2A17, 2A21, 2A25, 2A70, 2A80, 2A90, 2204, 2014, 2214, 2017, 2219, 2024, 2124) |

| 3000 Series | Aluminum-manganese Alloys(3A21, 3003, 3103, 3004, 3005, 3105) |

| 4000 Series | Al-Si Alloys(4A03, 4A11, 4A13, 4A17, 4004, 4032, 4043, 4043A, 4047, 4047A) |

| 5000 Series | Al-Mg Alloys(5A01, 5A03, 5A05, 5A06, 5B05, 5B06, 5A12, 5A13, 5A30, 5A66, 5005, 5019, 5050, 5251, 5052, 5154, 5454, 5754, 5056, 5456, 5082, 5083, 5182, 5183, In 5086) |

| 6000 Series | Aluminum Magnesium Silicon Alloys(6A12, 6B12, 6A51, 6101, 6005, 6060, 6061, 6063, 6063A, 6181, 6082) |

| 7000 Series | Aluminum, Zinc, Magnesium and Copper Alloys(7003, 7005, 7020, 7022, 7050, 7075, 7475, 7A01, 7A03, 7A04, 7A05, 7A09, 7A10, 7A15, 7A52) |

| 8000 Series | Other Alloys(8A06, 8011, 8090) |

Aluminum Grade

| Product name | Aluminum Sheet:0.15-6.0 Aluminum Plate:6.0-25.0 |

| Width(mm) | 20-2000mm or customized according to requirements |

| Thickness | 0.35mm-100mm or customized according to requirements |

| Length | According to the need to customize |

| Standard | GB, JIS, DIN, ASTM,ANSI |

| Surface treatment | Bright, polished, hairline, brush, sandblasting, grid, relief, etching, rolling surface finish, no stains, no rough edges, patterns, printing,brushed, mirror, embossed, sandblasted, etc |

| Temper | O, H12, H14, H16, H18, H112, H113, H19, H111, H22, H24, H26, H211, H32, H36, H38, H131, H151, H241, H261, H341, H361, F, T53, T6, T63, T6351, T651, T73, T7351, etc. |

| Type | Plate, sheet,strips,belt, thin plate, medium plate, thick plate, super thick plate, coil |

| Properties | Corrosion resistance, heat resistance, high hardness, good ductility |

| Production process | Hot rolling or cold rolling |

| Product application | Industry, transportation, building modeling, automobile, medical machinery, etc |

| Package | Standard export package, such as wooden box or as required. |

Mechanical properties

|

Aluminum Alloy |

Alloy State |

Thickness(mm) |

Tensile strength (Rm/Mpa) |

Yield strength (Rp0.2/Mpa) |

Elongation (%) |

Bending radius(α) |

Hardness( HBW)α |

||

|

A50mm |

A5.65 |

90° |

180° |

||||||

|

≥ |

|

||||||||

|

5754 |

F |

≥2.5~100 |

— |

— |

— |

— |

— |

— |

— |

|

>100.0~150.0 |

180 |

— |

— |

— |

— |

— |

— |

||

|

O |

>0.2~0.5 |

190~240 |

80 |

12 |

— |

0t |

0.5t |

38 |

|

|

>0.5~1.5 |

190~240 |

80 |

14 |

— |

0.5t |

0.5t |

38 |

||

|

>1.5~3.0 |

190~240 |

80 |

16 |

— |

1.0t |

1.0t |

38 |

||

|

>3.0~6.0 |

190~240 |

80 |

18 |

— |

1.0t |

1.0t |

38 |

||

|

>6.0~12.5 |

190~240 |

80 |

18 |

— |

2.0t |

— |

38 |

||

|

>12.5~100.0 |

190~240 |

80 |

— |

17 |

— |

— |

38 |

||

|

H112 |

>6.0~12.5 |

190 |

100 |

12 |

— |

— |

— |

62 |

|

|

>12.5~25.0 |

190 |

90 |

— |

10 |

— |

— |

58 |

||

|

>25.0~40.0 |

190 |

80 |

— |

12 |

— |

— |

52 |

||

|

>40.0~80.0 |

190 |

80 |

— |

14 |

— |

— |

52 |

||

|

H12 |

>0.2~0.5 |

220~270 |

170 |

4 |

— |

— |

— |

46 |

|

|

>0.5~1.5 |

220~270 |

170 |

5 |

— |

— |

— |

46 |

||

|

>1.5~3.0 |

220~270 |

170 |

6 |

— |

— |

— |

46 |

||

|

>3.0~6.0 |

220~270 |

170 |

7 |

— |

— |

— |

46 |

||

|

H14 |

>0.2~0.5 |

240~280 |

190 |

3 |

— |

— |

— |

54 |

|

|

>0.5~1.5 |

240~280 |

190 |

3 |

— |

— |

— |

60 |

||

|

>1.5~3.0 |

240~280 |

190 |

4 |

— |

— |

— |

60 |

||

|

>3.0~6.0 |

240~280 |

190 |

4 |

— |

— |

— |

60 |

||

Physical and chemical properties of product grade

1000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others: |

Others: |

Al: Min. |

|

Each |

Total |

||||||||||

|

1050 |

0.25 |

0.4 |

0.05 |

0.05 |

0.05 |

– |

0.05 |

0.03 |

0.03 |

– |

99.5 |

|

1050A |

0.25 |

0.4 |

0.05 |

0.05 |

0.05 |

– |

0.07 |

0.05 |

0.03 |

– |

99.5 |

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

– |

0.05 |

0.03 |

0.03 |

– |

99.6 |

|

1070 |

0.2 |

0.25 |

0.04 |

0.03 |

0.03 |

– |

0.04 |

0.03 |

0.03 |

– |

99.7 |

|

1100 |

0.95 Si + Fe |

0.05~0.20 |

0.05 |

– |

– |

0.1 |

– |

0.05 |

0.15 |

99 |

|

2000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al:Min. |

|

2A06 |

0.5 |

0.5 |

3.8-4.3 |

0.5-1.0 |

1.7-2.3 |

– |

0.1 |

0.03-0.15 |

the rest part |

|

2A16 |

0.3 |

0.3 |

6.0-7.0 |

0.4-0.8 |

0.05 |

– |

0.1 |

0.1-0.2 |

the rest part |

3000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al: Min. |

|

3003 |

0.6 |

0.7 |

0.05~0.20 |

1.0~ 1.5 |

— |

— |

0.1 |

— |

the rest part |

|

3004 |

0.3 |

0.7 |

0.25 |

1.0~ 1.5 |

0.8–1.3 |

— |

0.25 |

— |

the rest part |

|

3A21 |

0.6 |

0.7 |

0.05~0.20 |

1.0~ 1.5 |

— |

— |

0.1 |

— |

the rest part |

5000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other |

Al: Min. |

|

5052 |

≤0.25 |

≤0.40 |

≤0.10 |

≤0.10 |

2.2-2.8 |

0.15-0.35 |

≤ 0.1 |

/ |

≤ 0.05 |

the rest part |

|

5005 |

≤ 0.3 |

≤ 0.7 |

≤ 0.2 |

≤ 0.2 |

0.5 - 1.1 |

≤ 0.1 |

0.25 |

/ |

≤ 0.05 |

the rest part |

|

5083 |

≤ 0.4 |

≤0.40 |

≤0.10 |

0.4-1.0 |

4.0-4.9 |

0.05-0.25 |

≤ 0.25 |

/ |

≤ 0.05 |

the rest part |

|

5A05 |

≤ 0.5 |

≤0.50 |

≤0.10 |

0.3-0.6 |

4.8-5.5 |

/ |

≤ 0.20 |

/ |

≤ 0.05 |

the rest part |

6000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other |

Al: Min. |

|

6061 |

0.4-0.8 |

≤0.7 |

0.15-0.4 |

≤0.15 |

0.8-1.2 |

0.04-0.35 |

≤0.25 |

≤0.15 |

≤0.05 |

The rest part |

7000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other |

Al: Min. |

|

7075 |

≤0.4 |

≤0.5 |

1.2-2.0 |

≤0.30 |

2.1-2.9 |

0.18-0.28 |

5.1-6.1 |

≤0.2 |

≤0.05 |

the rest part |

8000 Series Aluminum Plate

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other |

Al: Min. |

|

8011 |

0.5-0.9 |

0.6-1 |

≤0.1 |

≤0.2 |

≤0.05 |

≤0.05 |

≤0.10 |

≤0.08 |

≤0.05 |

The rest part |

Mechanical properties

|

Aluminum Alloy |

Alloy State |

Thickness(mm) |

Tensile strength (Rm/Mpa) |

Yield strength (Rp0.2/Mpa) |

Elongation (%) |

|

5A05 |

O、H112 |

0.15-500 |

≥225 |

≥110 |

≥1 |

We can make all kinds of conventional aluminum plate and special specification aluminum plate according to the need.

If you have any inquiries and questions, please contact CONTINENTAL STEEL CO.,LTD. at any time. Thanks in advance. Welcome!