-

Connection methods of welded steel pipe

A welded steel pipe is a metal pipe produced by rolling steel plates and welding them into a specific diameter on a mold. Here's an overview of the connection methods of welded steel pipe.

2024-07-05

-

Uses of large diameter SSAW welded pipes

Large-diameter spiral submerged arc welded (SSAW) pipes are known for their exceptional quality and performance. Each step in their production process, from steel plate pretreatment to edge forming, internal welding, external welding, straightening, and cutting, is meticulously executed to ensure superior weld quality and pipe strength. These steel pipes boast high strength, high-quality welds, and long service life, earning widespread recognition and praise both within and outside the industry. Their excellent performance makes them indispensable in various fields, including petrochemical, slurry transportation, sand pumping, dredging, beaches, rivers, waterways, urban environmental protection, and engineering construction.

2024-07-04

-

Spiral submerged arc welding method of SSAW pipe

Spiral submerged arc welding (SSAW) steel pipes are extensively used in petroleum, chemical, and natural gas industries. The welding method is crucial for ensuring the quality and reliability of these steel pipes. This article outlines the welding method for SSAW steel pipes.

2024-07-04

-

Roughness of carbon welded steel pipe

The roughness of carbon welded steel pipes is determined by the smoothness of their surface. Common roughness measurements include Ra, Rz, and Rmax, typically ranging from Ra 1.6 to 6.3 microns. This article will briefly introduce the roughness of carbon welded steel pipe.

2024-07-04

-

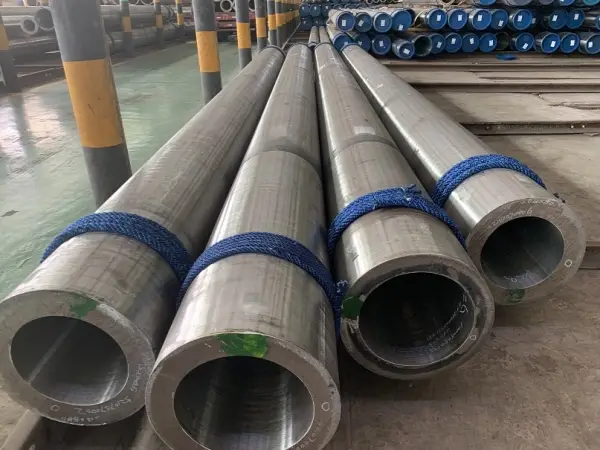

2195 seamless steel pipe material requirements

Seamless steel pipes are characterized by their lack of joints, offering superior mechanical properties and surface finishes both internally and externally. These pipes are produced through a process involving heating, perforating, expanding, cold drawing, or cold rolling of a solid steel billet. Their robust construction and finish make them invaluable across various industries.

2024-07-04

-

High-pressure boiler tube bending treatment method

High-pressure boilers are crucial mechanical equipment in industrial production, featuring pipes that are tightly connected to withstand high-temperature steam under high pressure. However, various factors can cause seamless pipes to bend and deform, leading to unstable equipment operation, leaks, and other issues. This article will briefly introduce high-pressure boiler tube bending treatment method.

2024-07-03

-

The role and principle of heat exchange tubes

Heat exchange tubes are integral components of heat exchangers, positioned inside the cylinder to facilitate the heat exchange between two media. They are characterized by high thermal conductivity and excellent isothermal properties. These tubes efficiently transfer heat energy from one point to another with minimal heat loss, earning them the title of heat transfer superconductors. Their thermal conductivity can be thousands of times that of copper.

2024-07-03

-

Material of seamless heat exchanger tube

Heat exchange tubes are integral components of heat exchangers, positioned inside the cylinder to facilitate the heat exchange between two media. They are characterized by high thermal conductivity and excellent isothermal properties. These tubes efficiently transfer heat energy from one point to another with minimal heat loss, earning them the title of heat transfer superconductors. Their thermal conductivity can be thousands of times that of copper.

2024-07-03

-

How to prevent decarburization of seamless carbon steel pipes

Surface decarburization in seamless pipes is primarily caused by oxidizing gases such as oxygen, water vapor, and carbon dioxide. When these gases come into contact with the heated surface of steel wires, simultaneous oxidation and decarburization occur. The solid solution carbon in iron has a high affinity for these gases, leading to the carbon on the surface being decarbonized.

2024-07-03

-

ERW steel pipe production line

ERW (Electric Resistance Welding) steel pipe utilizes induction welding, which requires no weld filler, produces no welding spatter, has a narrow heat-affected zone, and results in aesthetically pleasing welds with excellent mechanical properties. This makes ERW steel pipes highly desirable in various industries. The ERW steel pipe production line is among the most advanced globally, with key equipment supplied by leading manufacturers such as Germany's SMS and MEER. This article details the ERW steel pipe production line.

2024-07-02

-

Types of heat exchanger tubes

Heat exchanger tubes are crucial components within heat exchangers, facilitating the transfer of heat between two media. These tubes boast high thermal conductivity and excellent isothermal performance, making them highly efficient in transferring heat with minimal loss. Often referred to as heat transfer superconductors, their thermal conductivity is significantly higher than that of copper. This article will detail the various types of heat exchanger tubes.

2024-07-02

-

Anti-rust methods for seamless steel pipes

Ensuring the longevity and durability of seamless steel pipes requires effective anti-rust methods. Here are some of the most effective techniques.

2024-07-02