-

What standards referred to carbon steel plate?

Carbon steel plates are widely used in construction, manufacturing, energy, and infrastructure projects, adhering to various international and national standards. These standards define the chemical composition, mechanical properties, heat treatment requirements, and testing methods to ensure quality and performance. Below are some of the most commonly referenced standards for carbon steel plates.

2025-03-26

-

Corrosion resistant conventional galvanized steel pipe

Conventional galvanized steel pipes are steel pipes that have undergone a hot-dip galvanization process, providing them with excellent corrosion resistance. These pipes are widely utilized in construction, mechanical manufacturing, road infrastructure, and other industries. The galvanization process involves immersing the steel pipe in molten zinc, forming a protective zinc coating that prevents rust and corrosion.

2025-03-25

-

Carbon steel seamless pipe vs black carbon steel pipe

Both carbon steel seamless pipes and black carbon steel pipes are widely used in industrial applications, but they differ in manufacturing process, composition, mechanical properties, surface quality, and application scenarios. Understanding these differences helps in selecting the right pipe for specific requirements.

2025-03-25

-

How to deal with rust on pipe flanges?

When pipe flanges are rusted, the following treatment methods can effectively address the issue.

2025-03-24

-

Single flange steel pipes in industrial projects

Steel pipes play a crucial role in modern construction, engineering, and manufacturing. Among them, single flange steel pipes stand out due to their unique characteristics and diverse application scenarios. As a widely used construction material, steel pipes serve in structural frameworks, pipeline systems, and machinery manufacturing. Single flange steel pipes, as a specialized form, offer distinct advantages that make them suitable for various industrial needs.

2025-03-24

-

An overview of SS400 carbon structural steel

SS400 structural steel is a widely used carbon structural steel grade specified by the Japanese JIS standard. It features medium strength, good plasticity, and excellent welding performance, making it a preferred choice in various construction and engineering applications. The following sections provide a detailed overview of SS400 structural steel.

2025-03-21

-

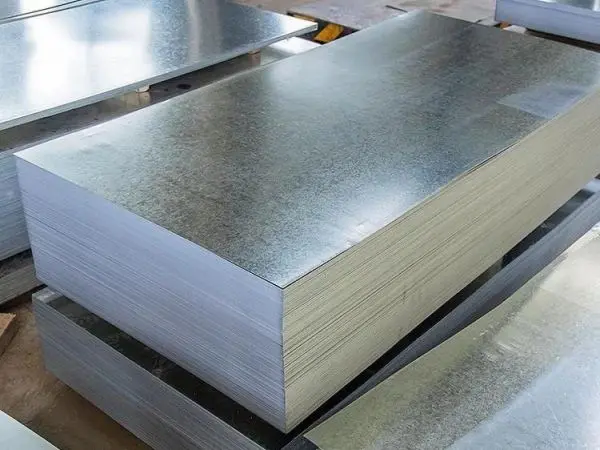

Galvanized layer thickness standards for galvanized sheet metal

The standards for galvanized layer thickness in galvanized sheets are established to ensure that the workpiece meets varying thickness requirements after galvanization. The required thickness of the galvanized layer depends on the thickness of the workpiece, with different standards for average and local thickness measurements.

2025-03-21

-

What factors affect the performance of galvanized steel pipes?

Galvanized steel pipes are widely used across various industries due to their durability, corrosion resistance, and strength. Let's explore the key elements that influence their performance.

2025-03-20

-

How to weld stainless steel mirror panels?

When welding stainless steel mirror panels, several factors must be carefully managed to maintain precision, prevent defects, and ensure a high-quality finish. Below are the most common issues and their solutions.

2025-03-20

-

Difference between black steel pipe and galvanized steel pipe

Black steel pipes and galvanized steel pipes are two commonly used types of steel pipes, each with distinct properties, applications, and advantages. Here’s a detailed comparison ofblack steel pipe and galvanized steel pipe.

2025-03-19

-

Key points of heat treatment of galvanized steel pipes

Galvanized steel pipe is a type of welded steel pipe that undergoes surface treatment through either hot-dip or electro-galvanizing processes, using Q235 steel as its base material. The primary advantage of this pipe lies in the protective zinc coating, which forms a dense barrier against oxidation and corrosion, significantly enhancing its durability while maintaining a cost-effective profile. Due to its excellent corrosion resistance and affordability, galvanized steel pipes are widely used in building water supply and drainage systems, municipal pipeline engineering, power cable protection, and scaffolding construction. They serve as a practical and long-lasting solution for transporting water, gas, and oil, combining both strength and versatility.

2025-03-19

-

Introduction of hot-rolled steel sheet piles

Hot-rolled steel sheet piles are specialized steel components equipped with interlocking locks, allowing them to connect seamlessly to form continuous and watertight retaining walls or water-resistant structures. Currently, these sheet piles are available in Z-type, U-type, and straight-belly cross-sectional designs, making them a preferred choice in various construction projects. This article will briefly introduce hot-rolled steel sheet piles.

2025-03-18